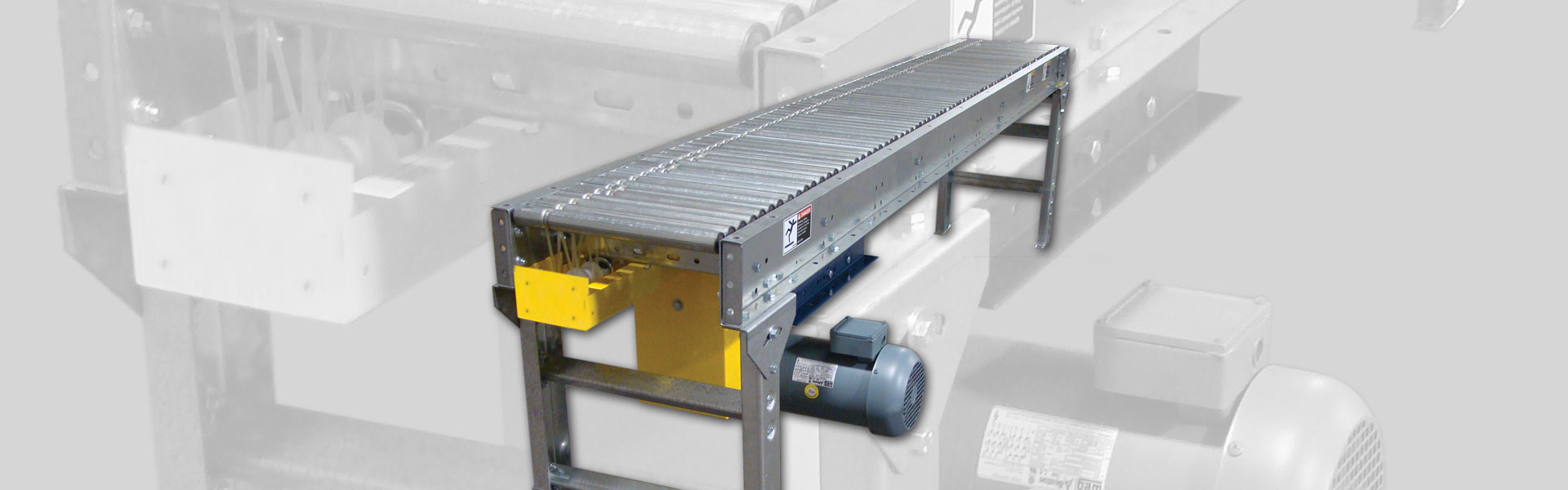

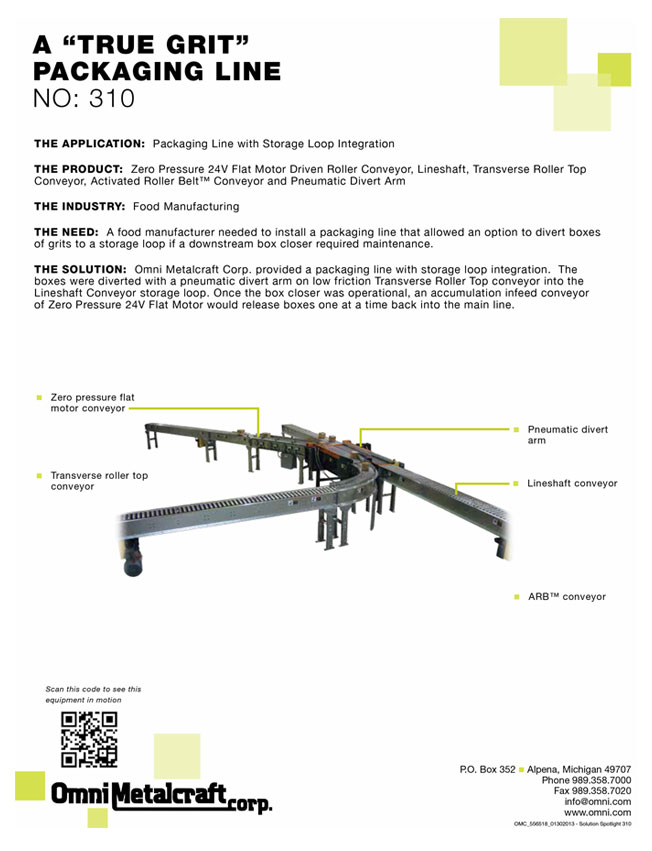

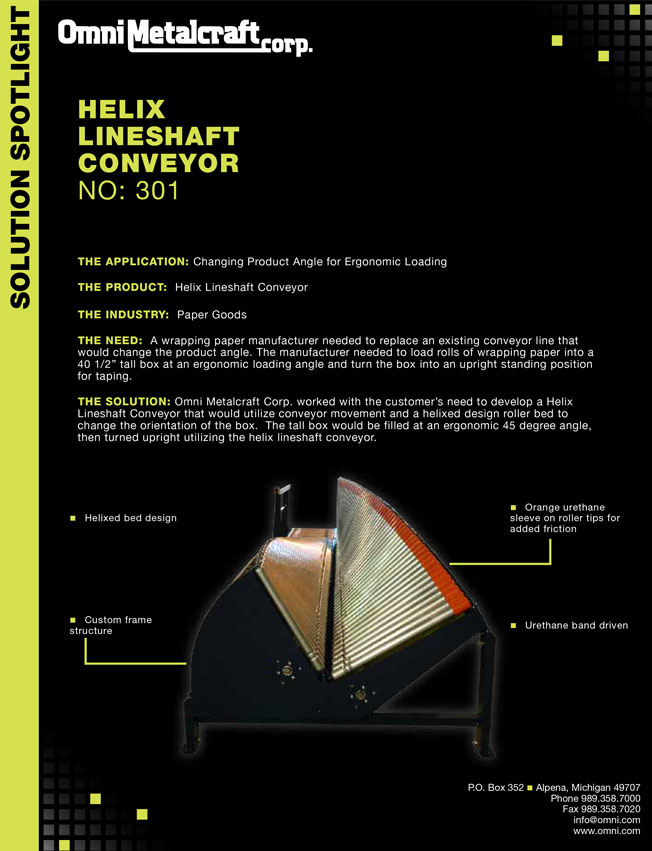

Lineshaft Driven Live Roller Conveyor

An Energy Efficient Means of Conveying

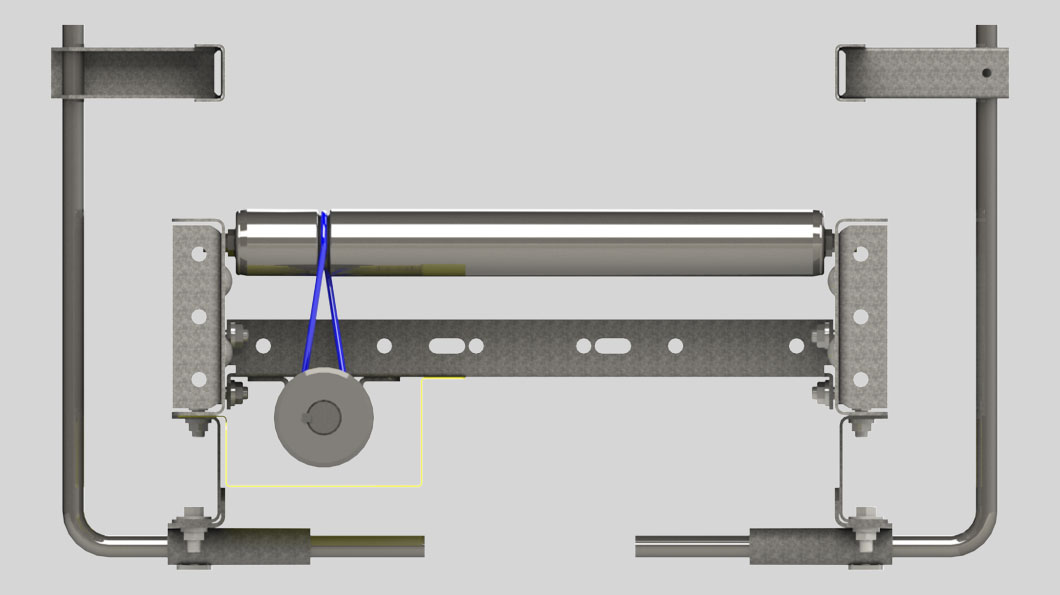

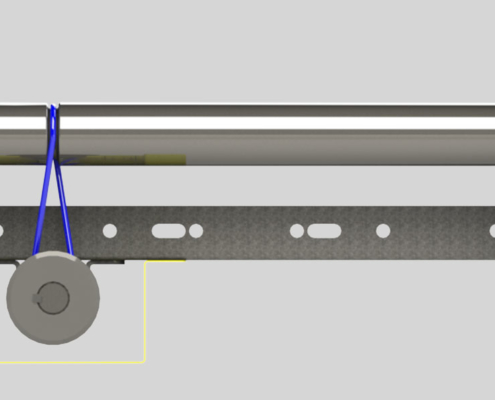

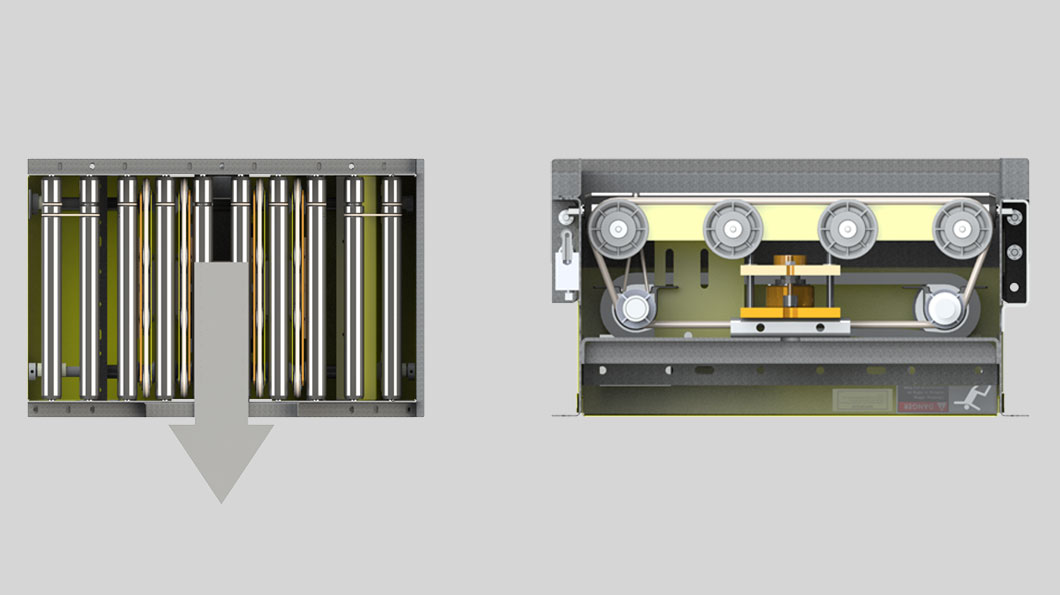

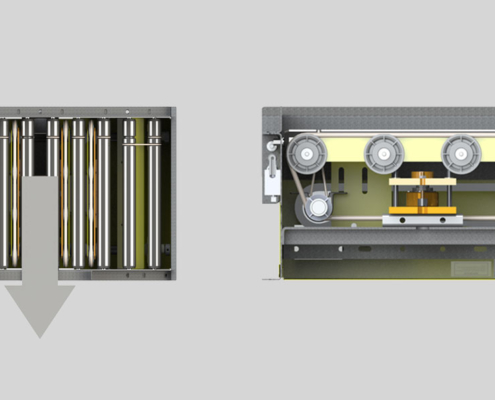

Lineshaft Driven Live Roller Conveyor (LS) is optimal for conveying light products (15 lbs./roller) at speeds of 25 to 120 FPM. They are designed for flat-bottomed, evenly distributed loads, such as those found in distribution and warehousing, food packaging and parcel handling. One motor can power up to 100 feet of conveyor, reducing costs of power consumption, installation and maintenance.

- Economical conveyance of loads up to 75 lbs. or 15 lbs. per roller

- Easy add slaved components; curves, spurs and transfers

- Increased driving force with optional keyed spools and high tension bands

- Full line of standard modular accessories

- Common applications include box, tote or tray transportation and minimum pressure accumulation

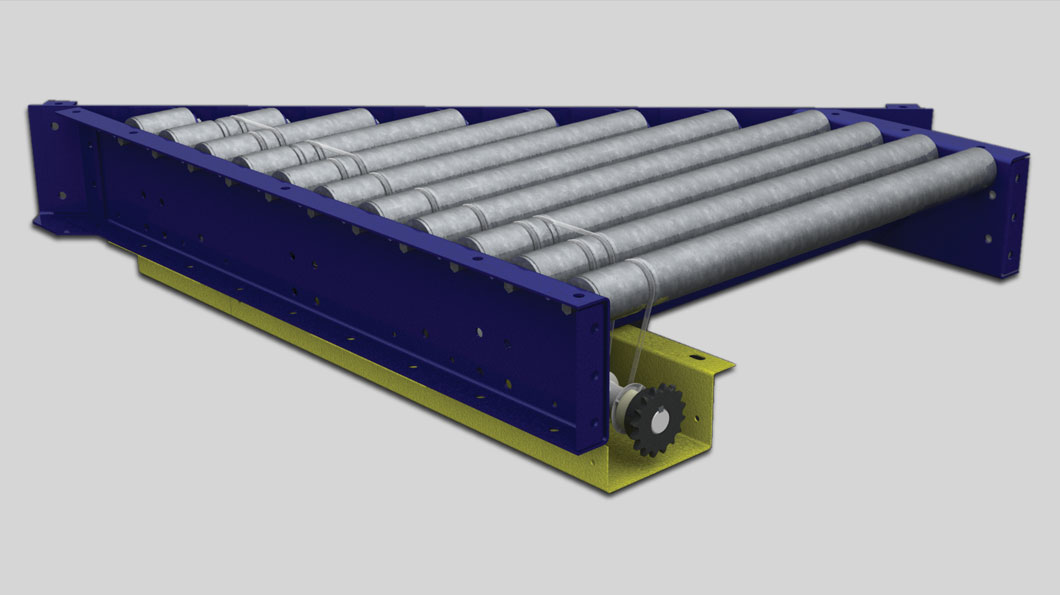

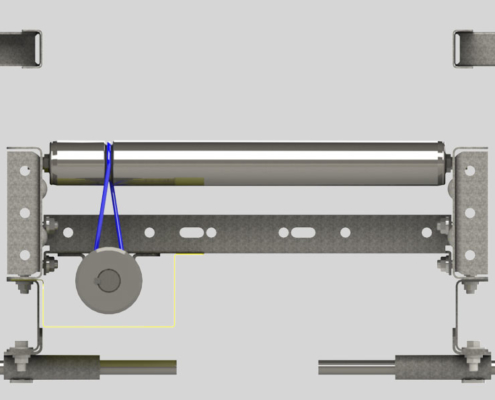

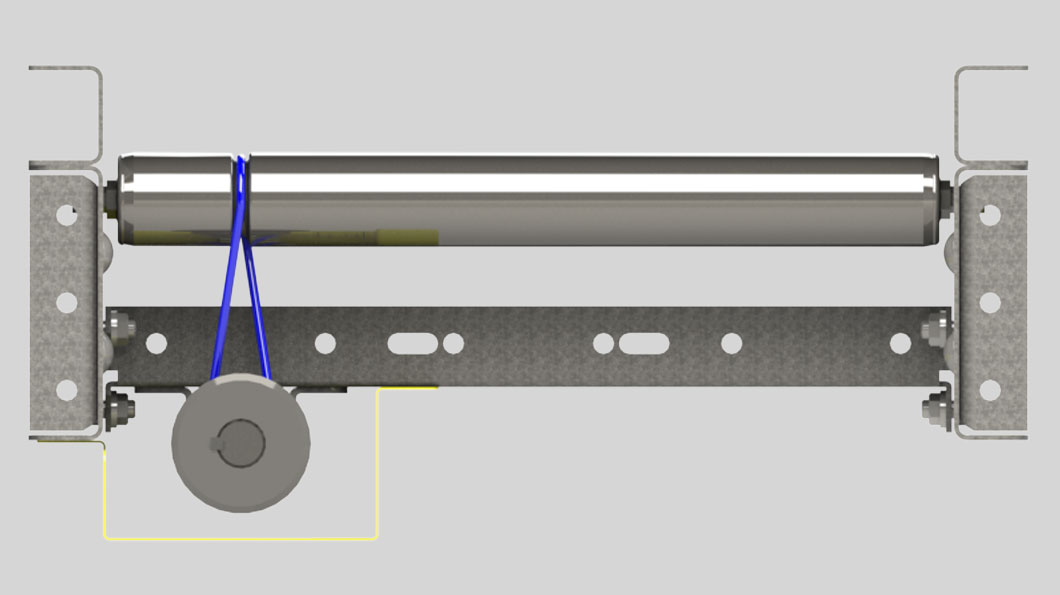

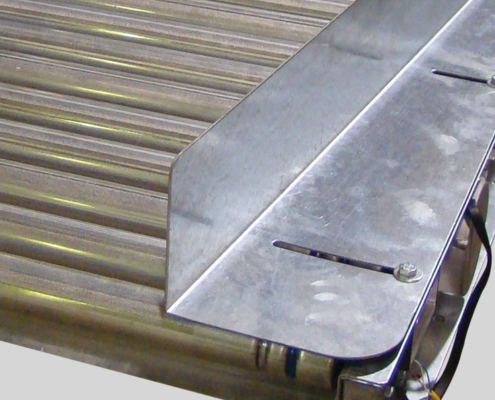

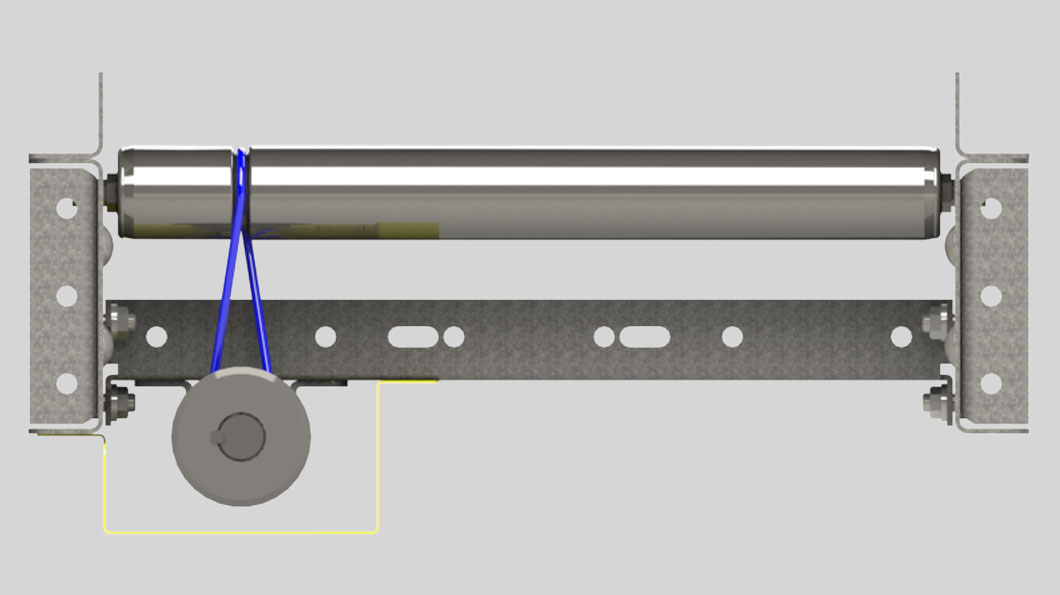

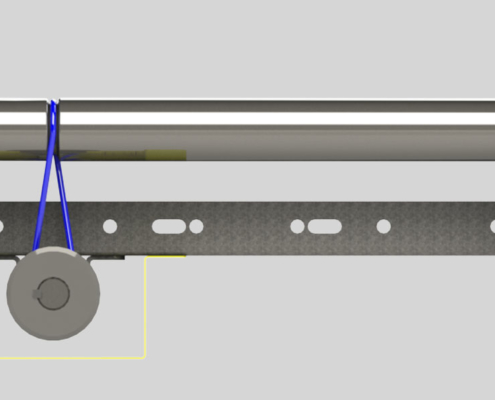

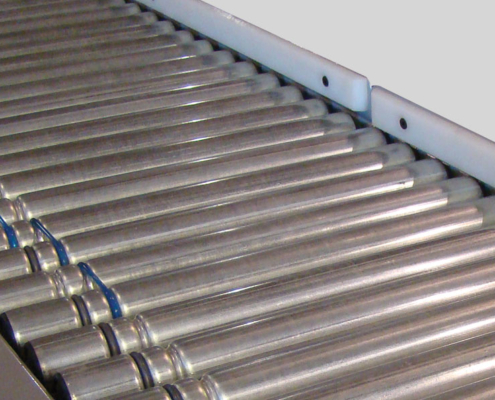

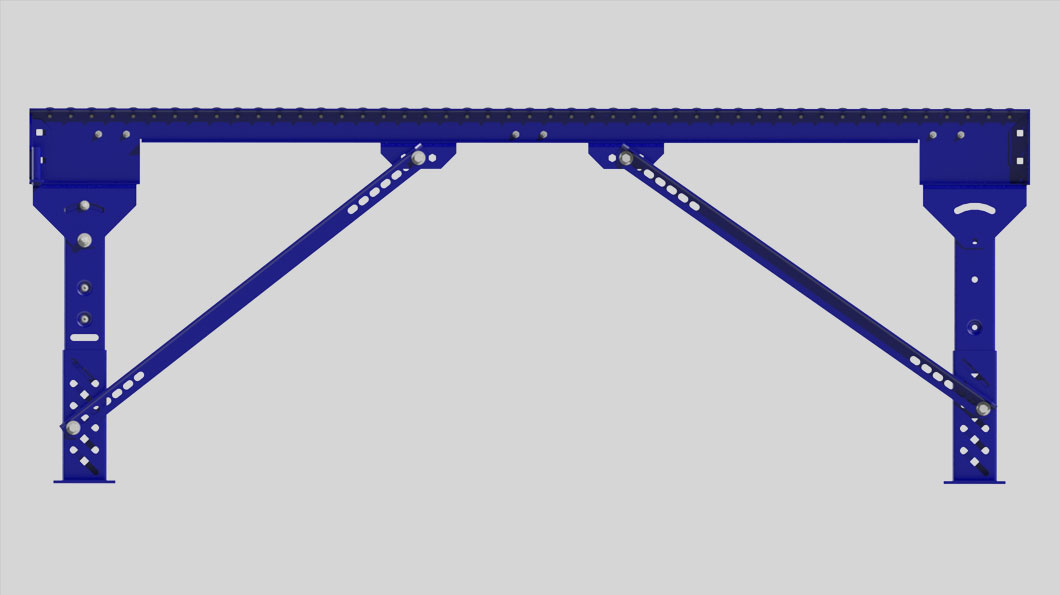

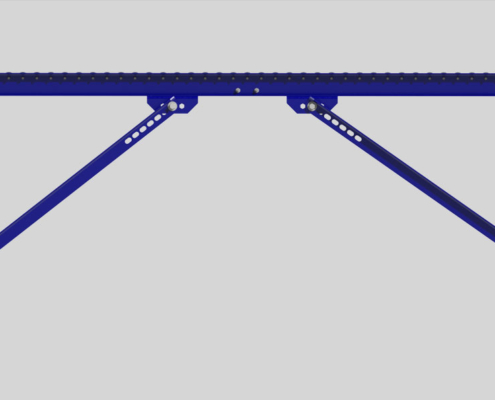

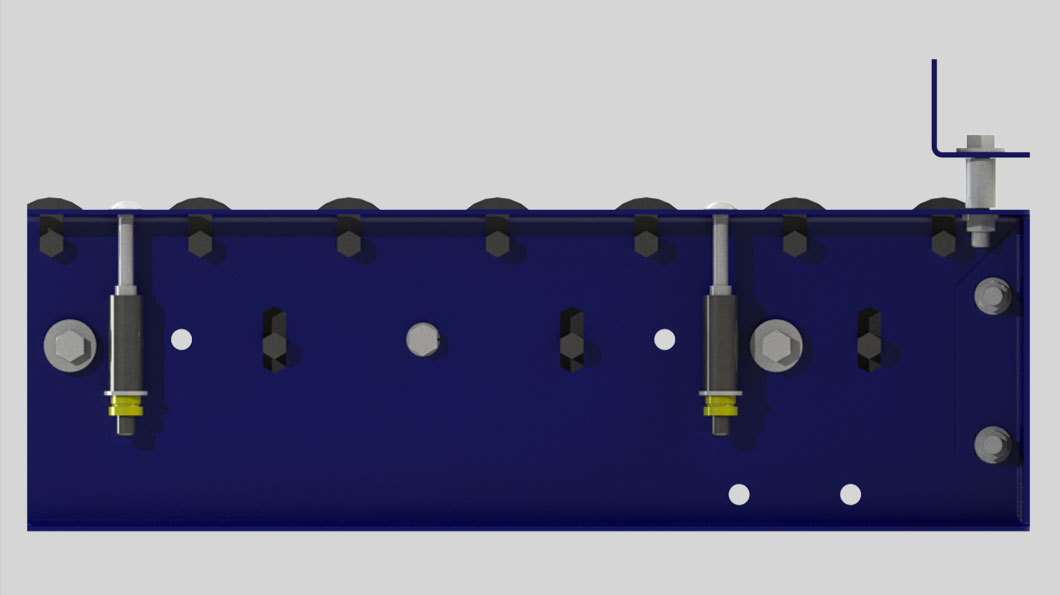

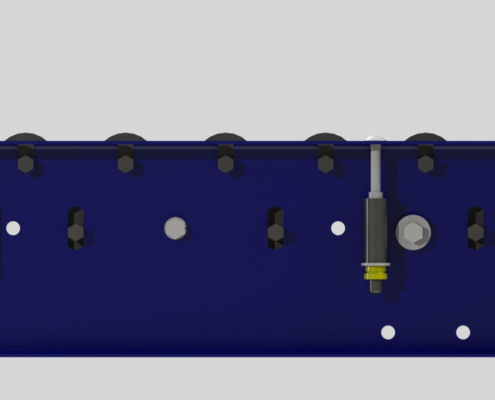

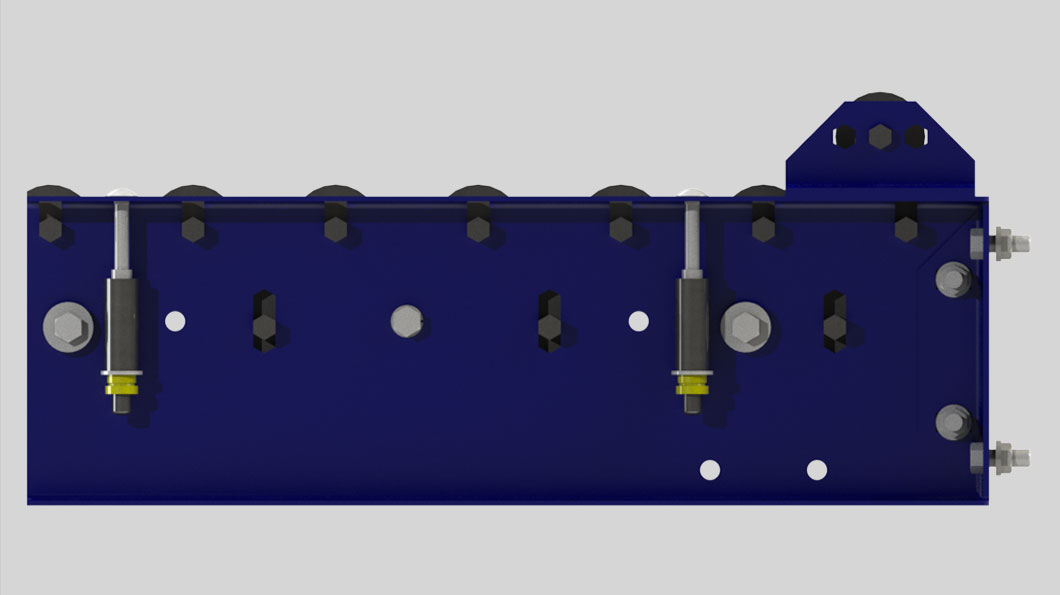

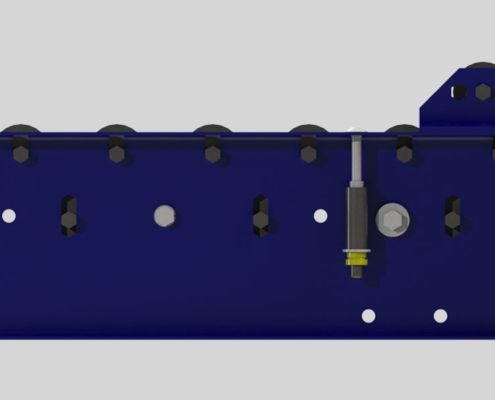

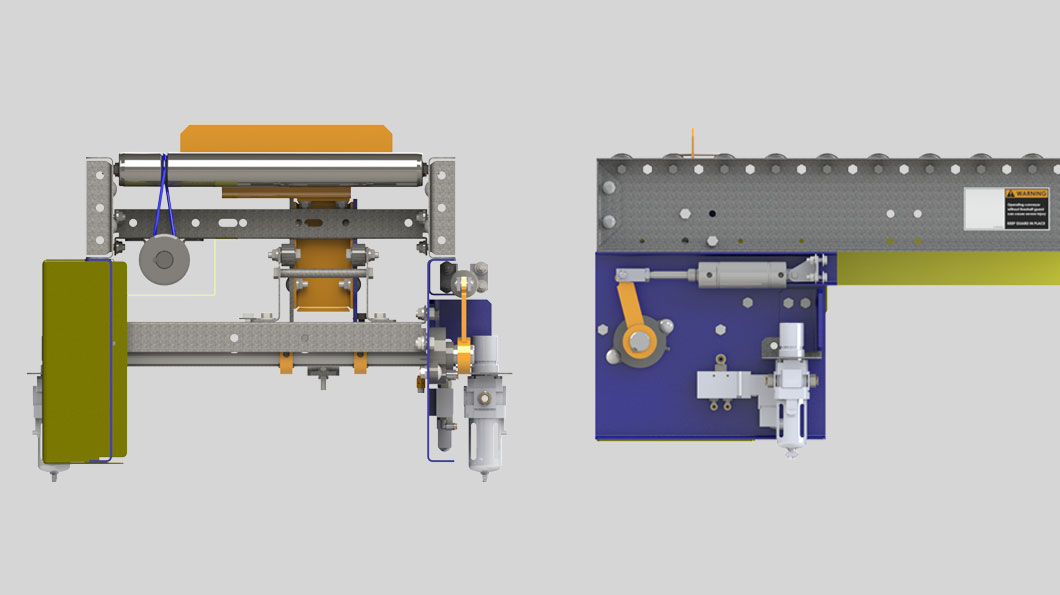

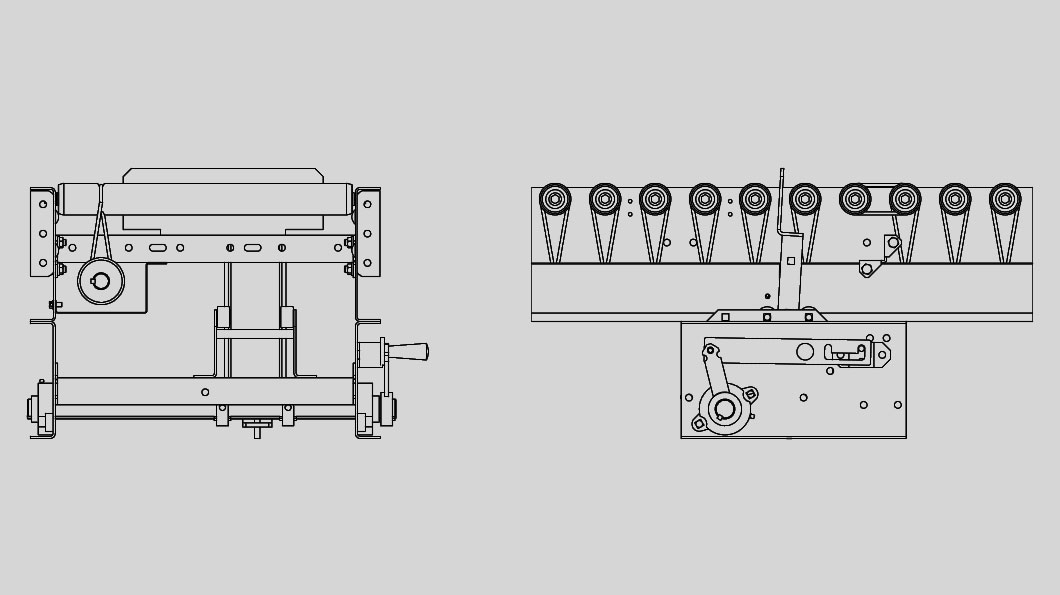

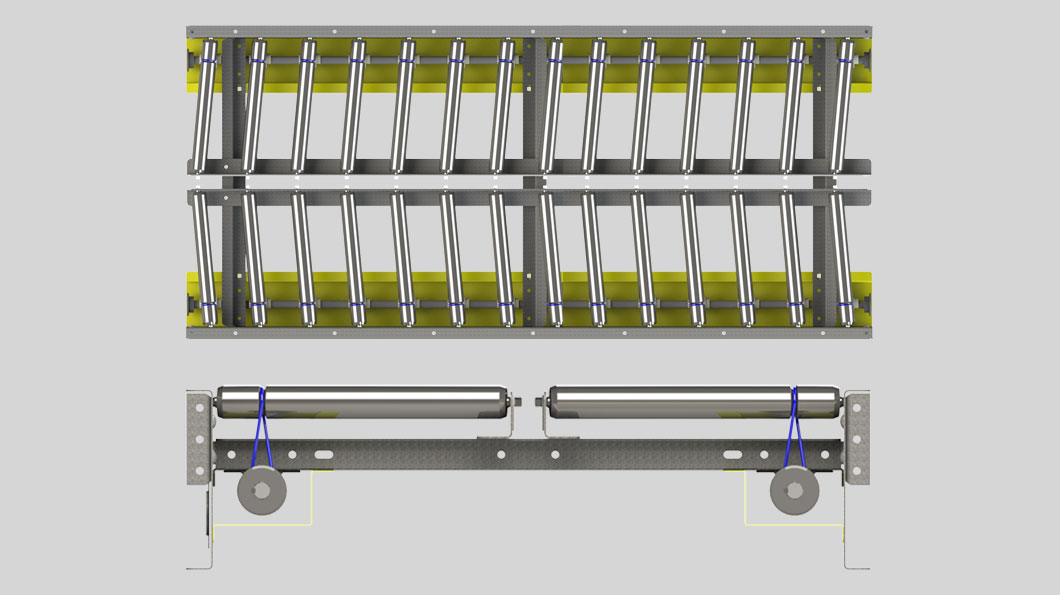

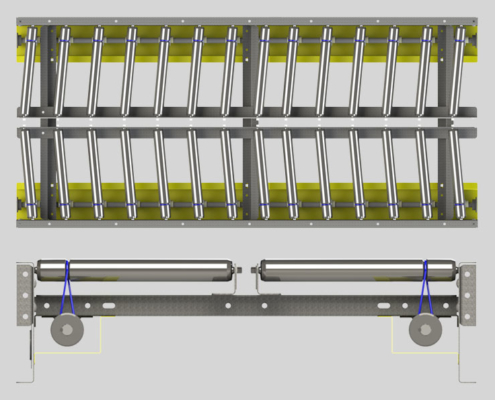

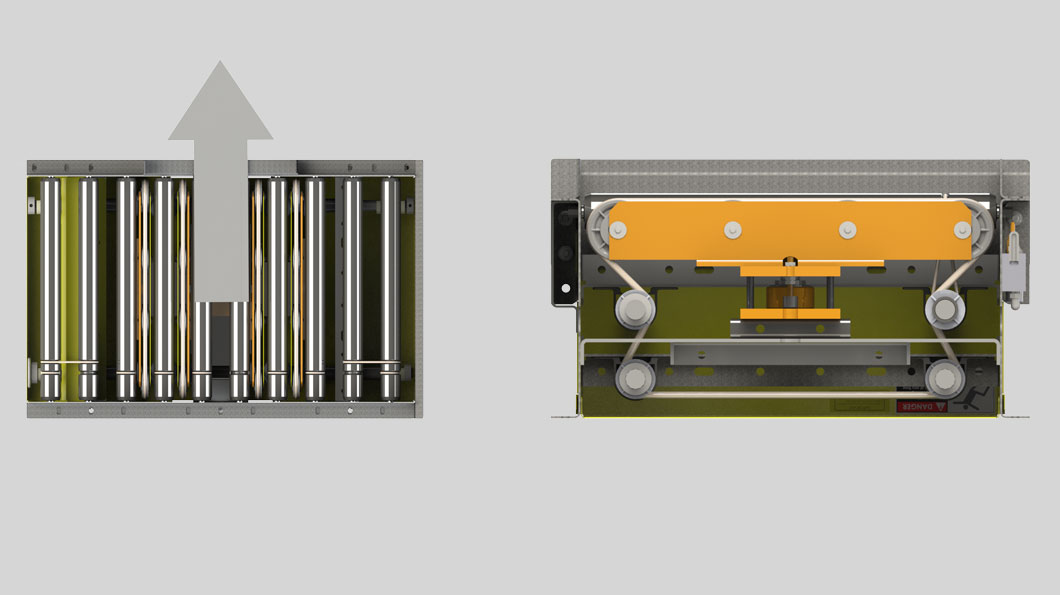

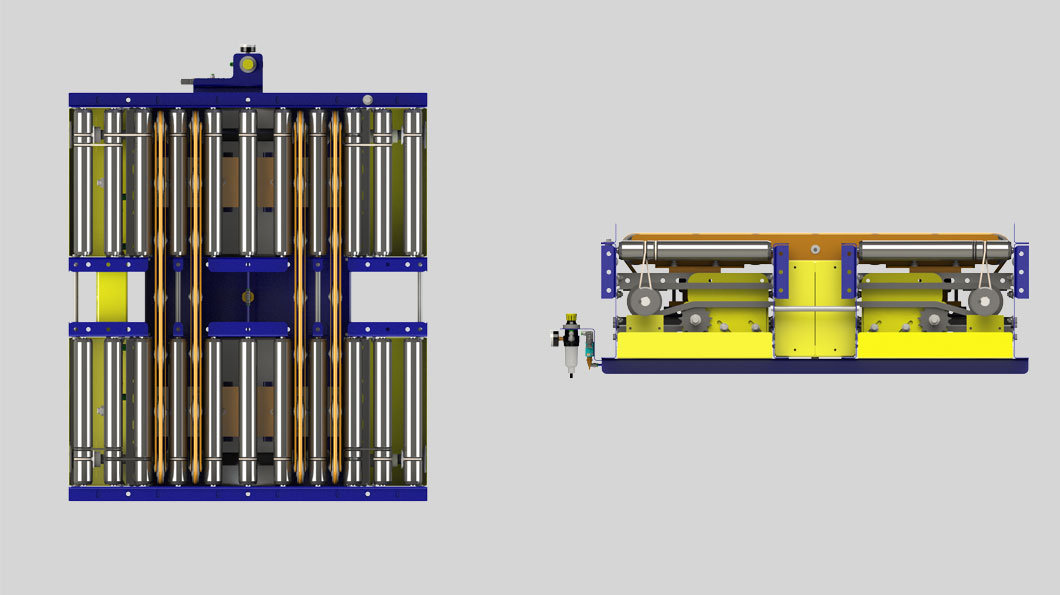

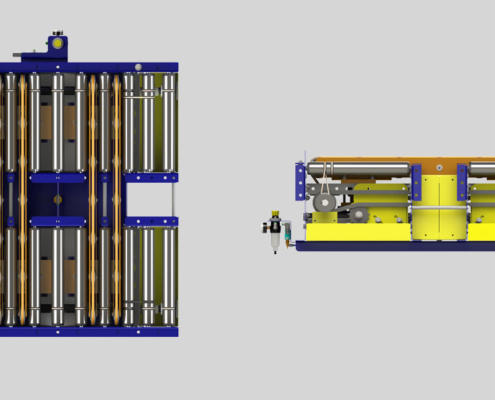

1.4” DIA. LINESHAFT DRIVEN LIVE ROLLER CONVEYOR

- Minimum back pressure accumulation

- 1 3/8″ dia. x 16 ga. galvanized roller

- Reversible with constant speed of 60 FPM

- 16 Between frame widths from 10″ to 28″

- Slaved sections 1′ to 10′

- Single drive powers straight sections, curves and spurs

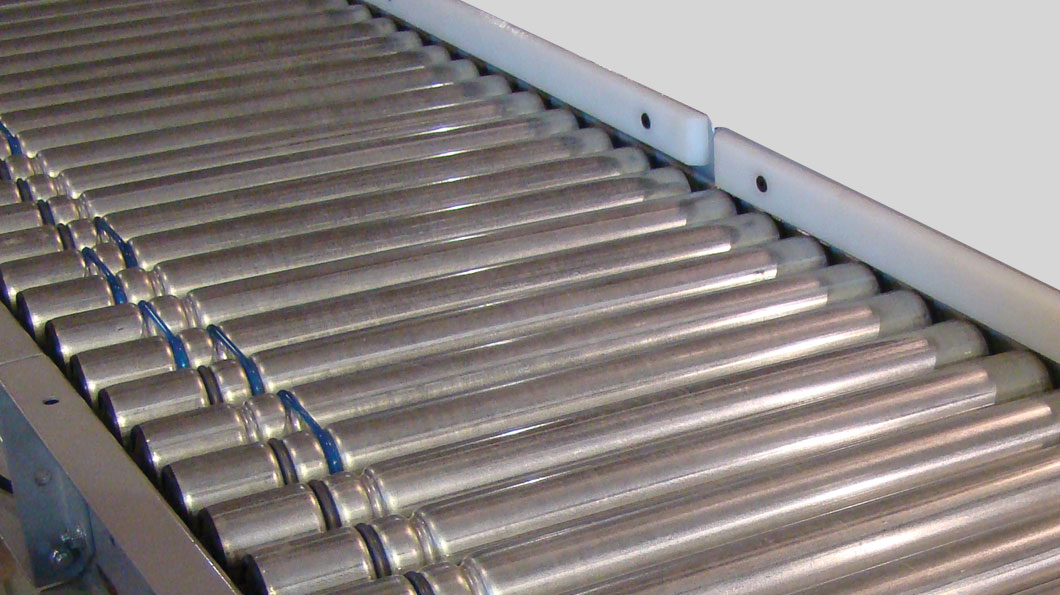

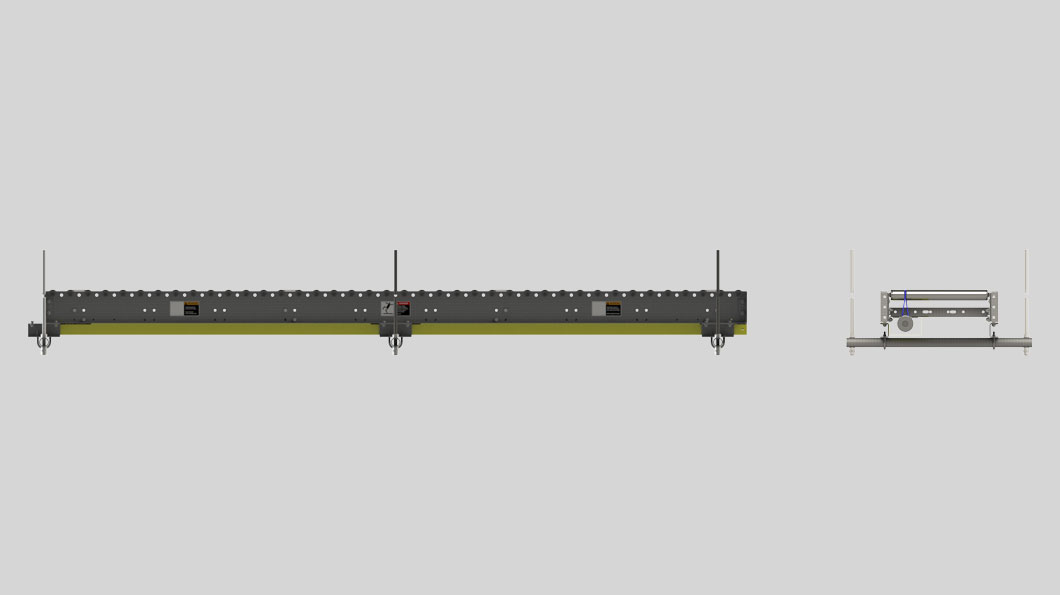

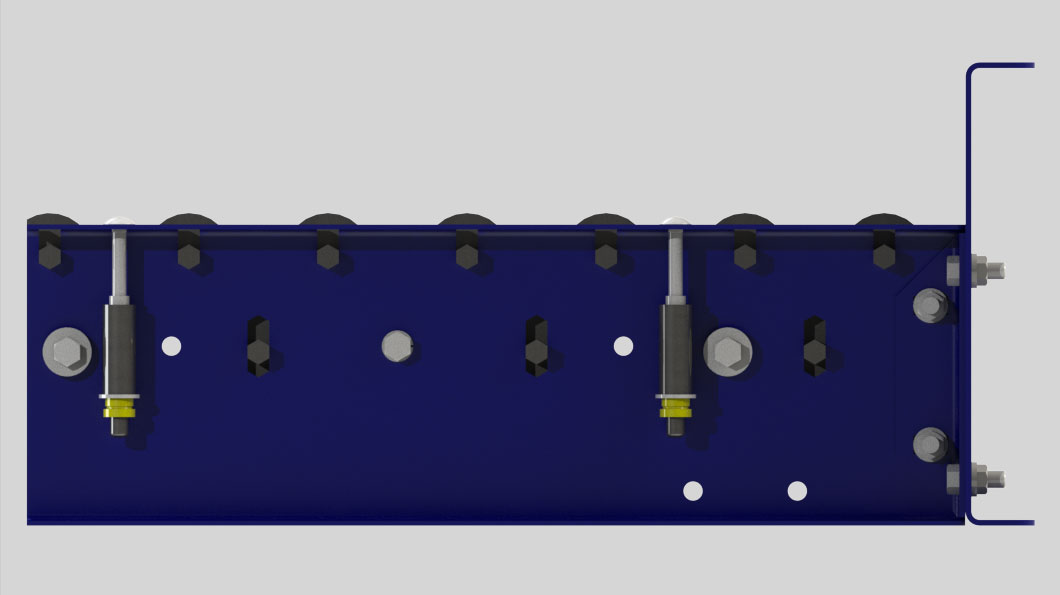

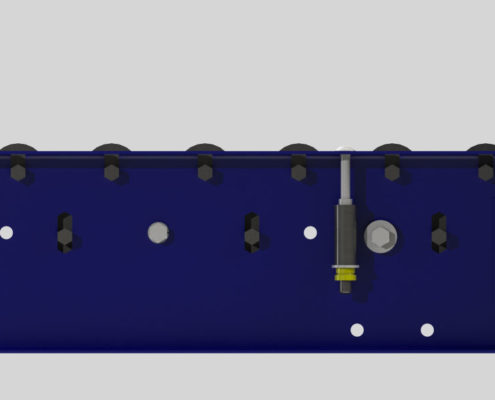

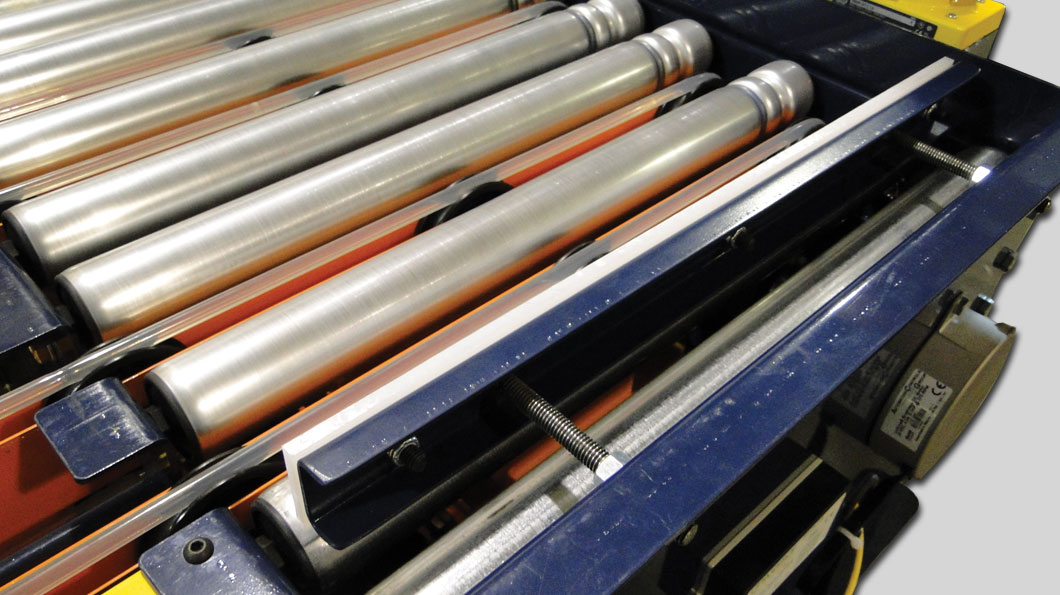

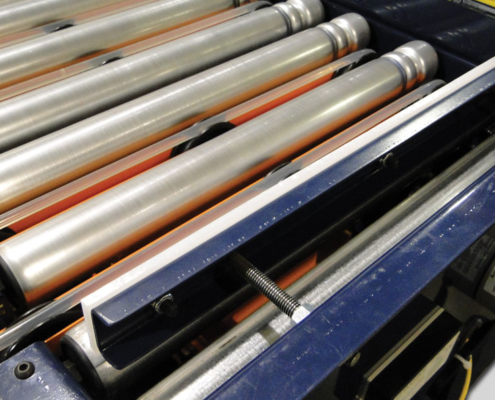

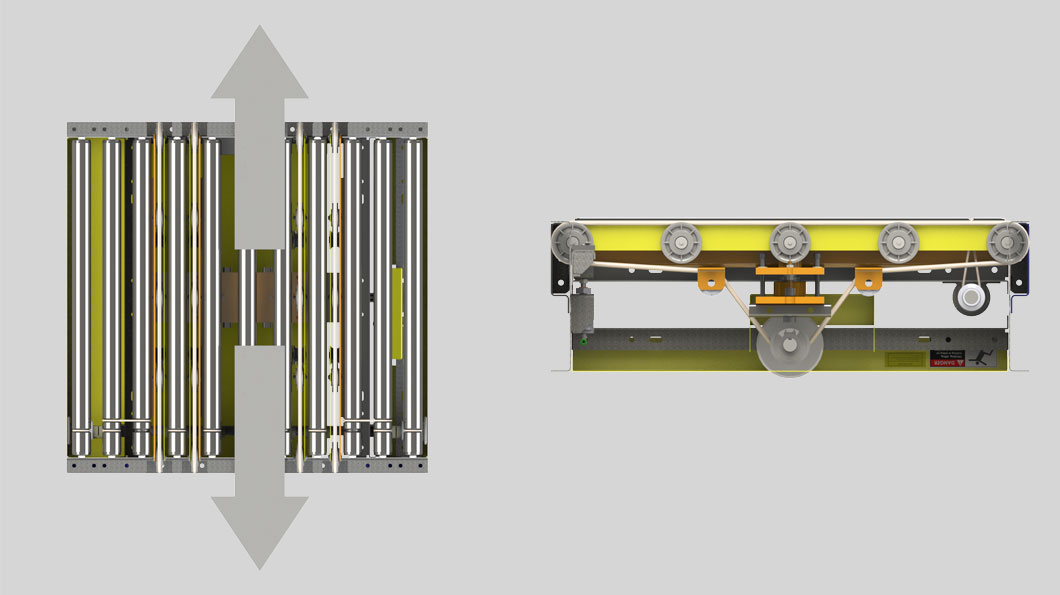

1.9” DIA. LINESHAFT DRIVEN LIVE ROLLER CONVEYOR

- Minimum back pressure accumulation

- 1.9″ dia. x 16 ga. galvanized roller

- Reversible with constant speed of 60 FPM

- 27 Between frame widths from 13″ to 39″

- Slaved sections 1′ to 10′

- Single drive powers straight sections, curves and spurs

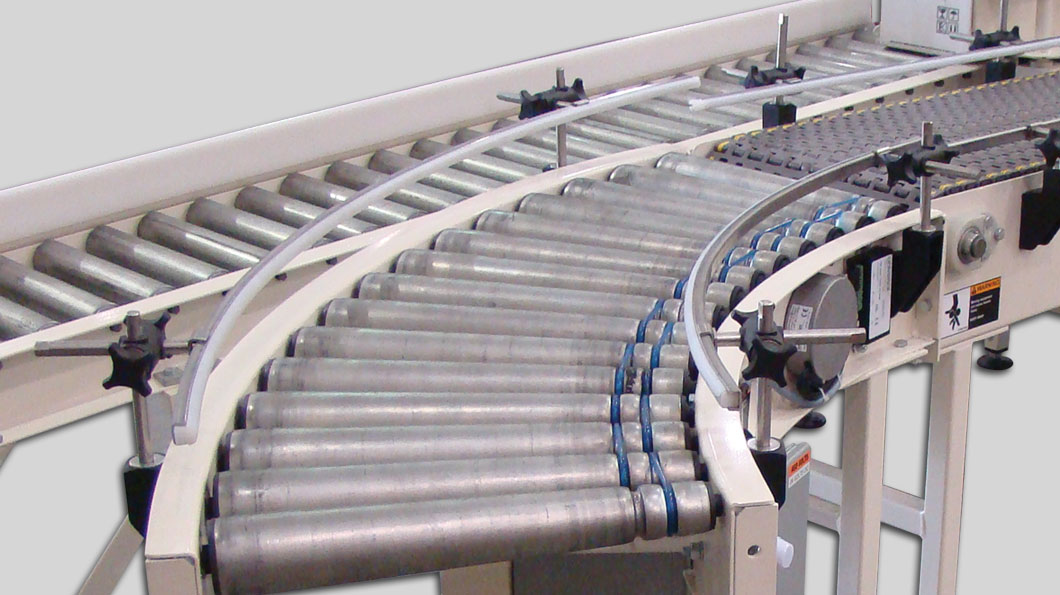

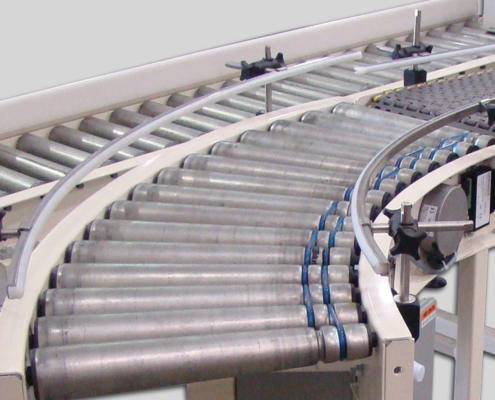

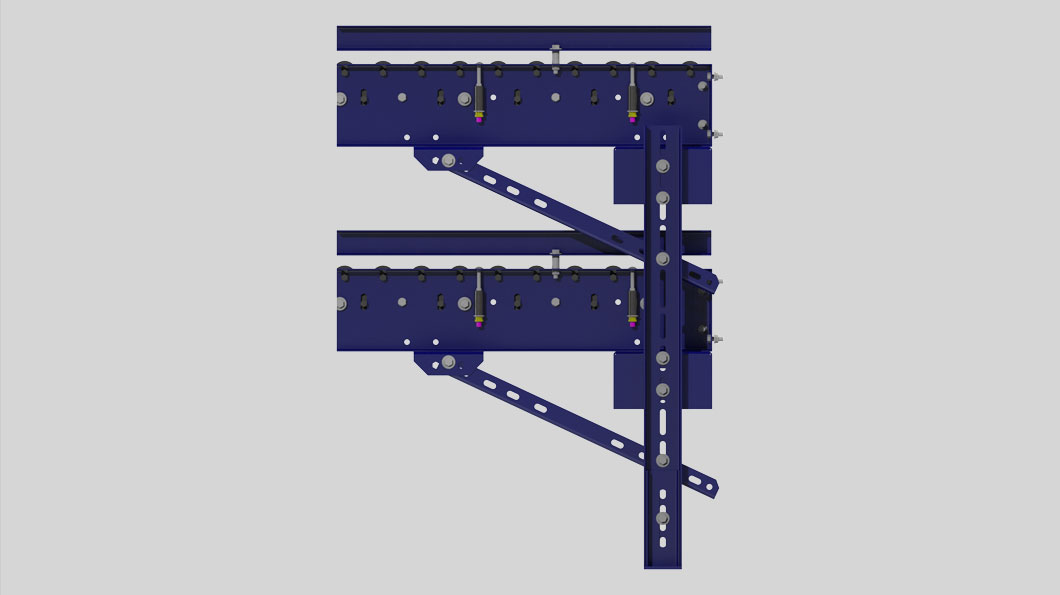

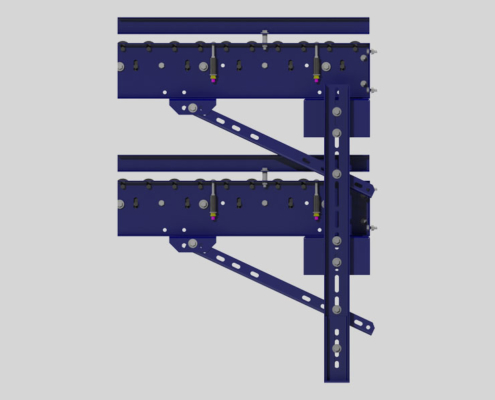

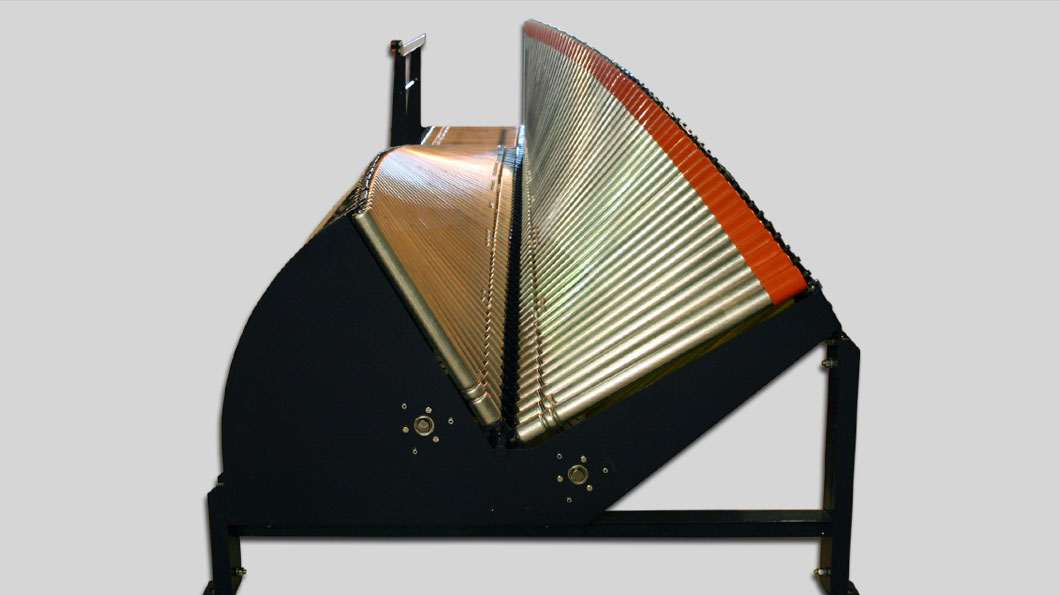

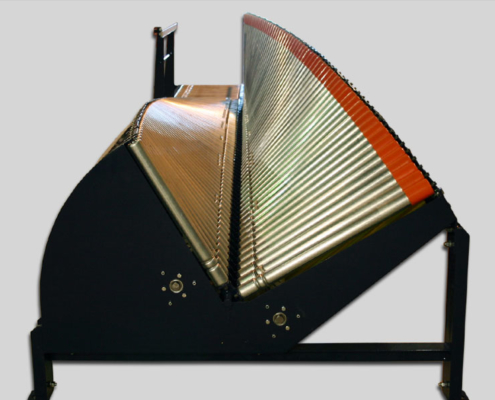

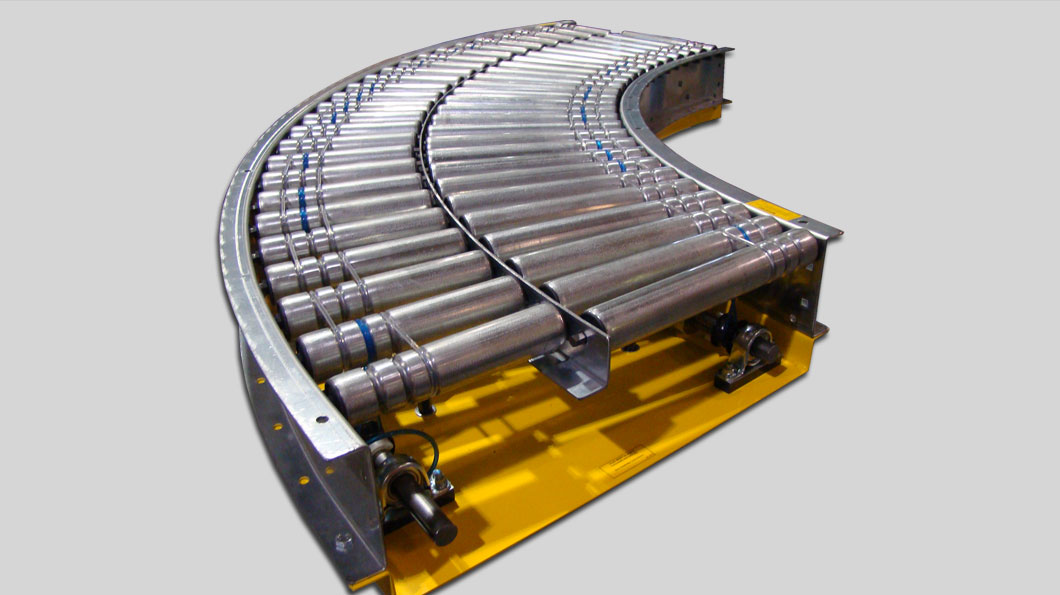

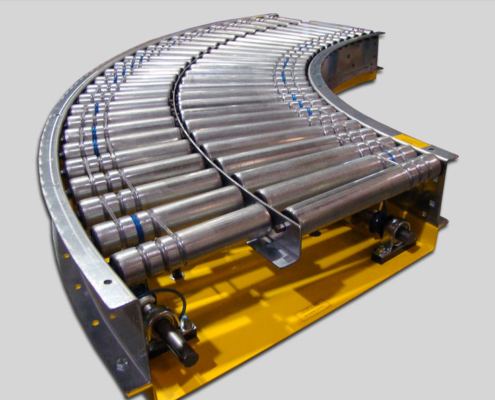

1.4” DIA. LINESHAFT DRIVEN CURVE AND SPUR CONVEYOR

- Curves – 1” to 1/1-2” dia. x 18 ga. tapered rollers

- Spurs – 1.4” dia. x 16 ga. straight rollers

- Slave driven from straight section or powered by own drive

- 30°, 45°, 60° and 90° curves

- 30° and 45° spurs

- Between frame widths from 10” to 28”

- Curves are for transportation only

1.9” DIA. LINESHAFT DRIVEN CURVE AND SPUR CONVEYOR

- Curves – 1-11/16” to 2-1/12” dia. x 14 ga. tapered rollers

- Spurs – 1.9” dia. x 16 ga. straight rollers

- Slave driven from straight section or powered by own drive

- 30°, 45°, 60° and 90° curves

- 30° and 45° spurs

- Between frame widths from 13” to 39”

- Curves are for transportation only

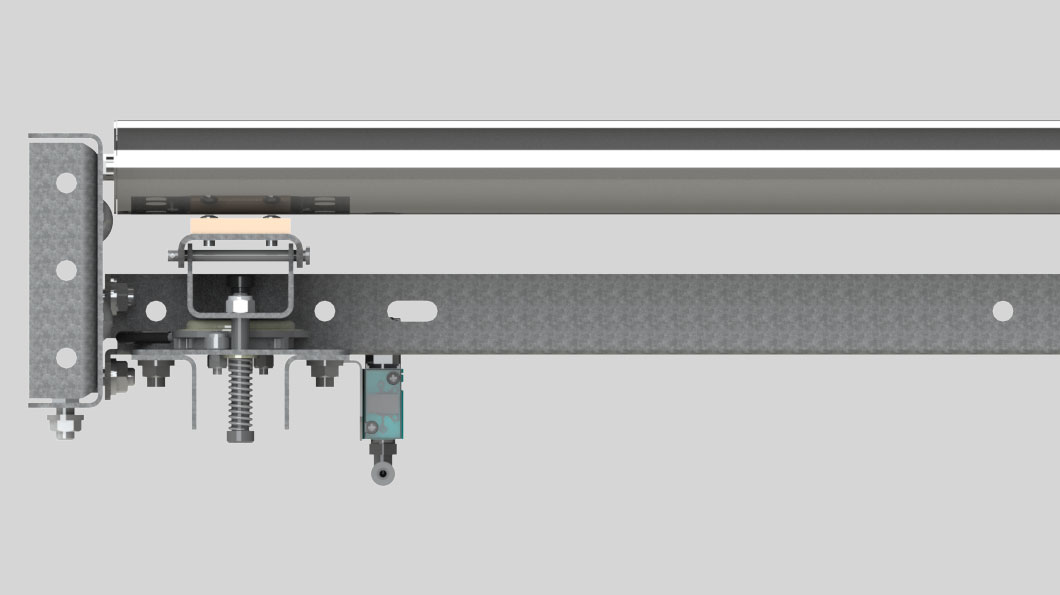

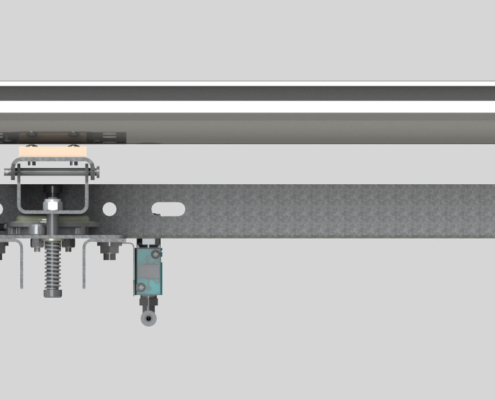

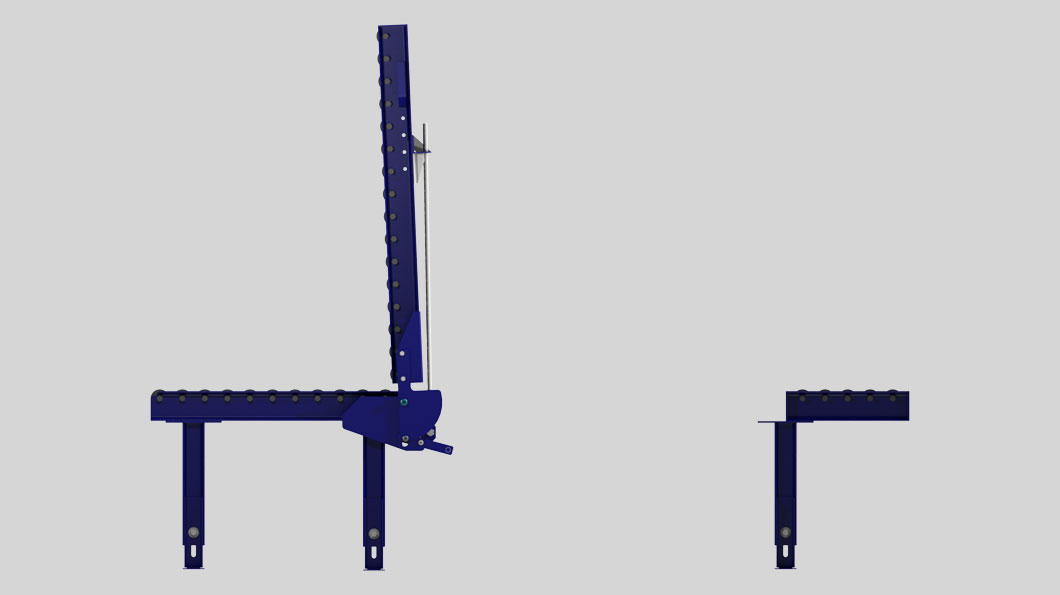

LINESHAFT STRAIGHT SPUR

- 1.4” dia. x 18 ga. galvanized rollers or 1.9” dia. x 16 ga. galvanized rollers

- Slave driven from straight section or powered by own drive

- Right hand or left hand

- Between frame widths from 10” to 39”

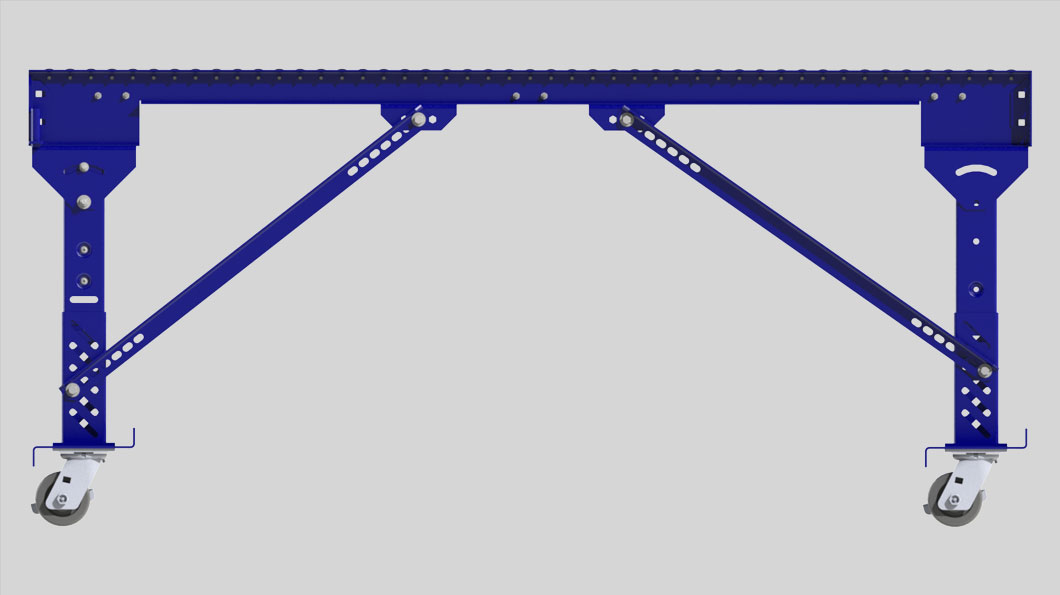

OPTIONAL EQUIPMENT AND DEVICES

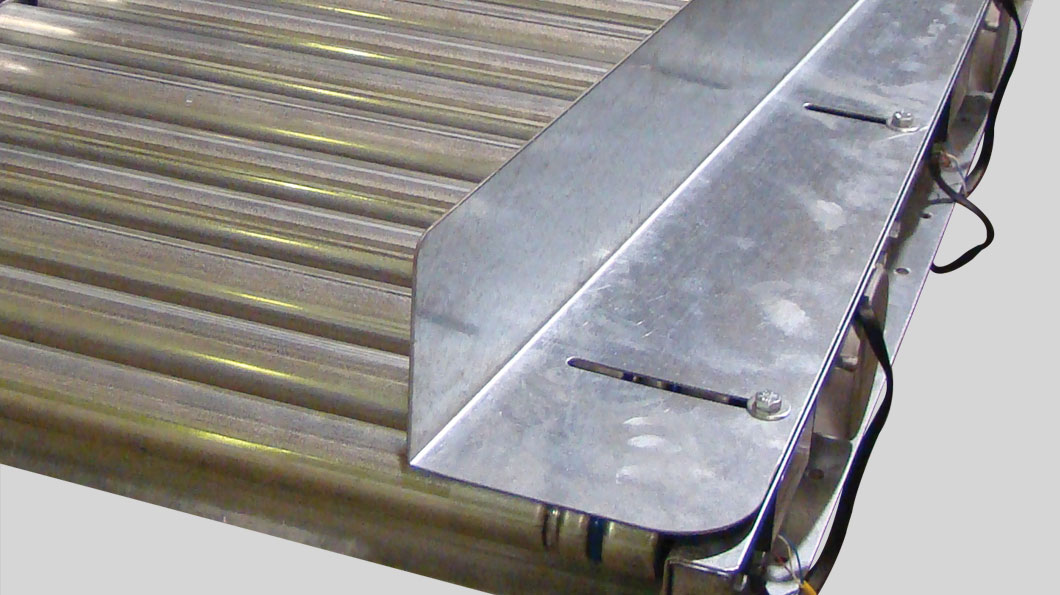

▸ Side Guides

▸ Supports

▸ Ceiling Hangers

▸ End Stops

▸ Blade Stops

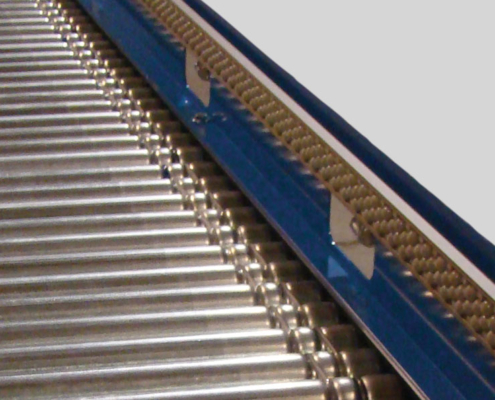

▸ Herringbone

▸ Urethane Belt Transfer Devices

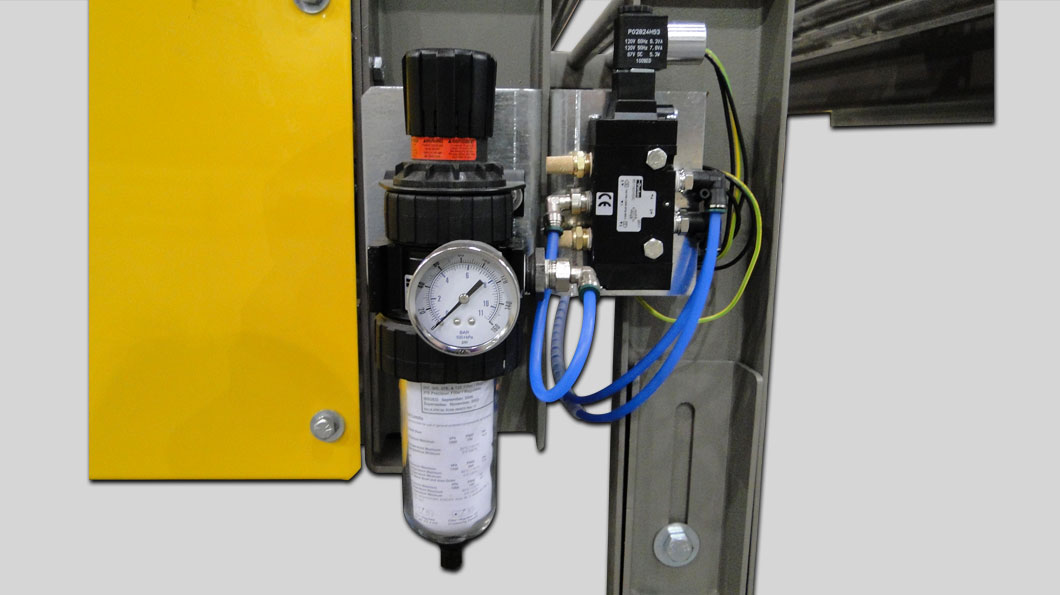

▸ Pneumatic Roller Brake

▸ Spring Assisted Lift Gate Section

▸ Roller Coatings or Sleeves

LINESHAFT DRIVEN LIVE ROLLER CONVEYOR RESOURCES

▸ Photos

▸ Quote Worksheets (PDF)

▸ Lineshaft Driven Live Roller Conveyor Literature