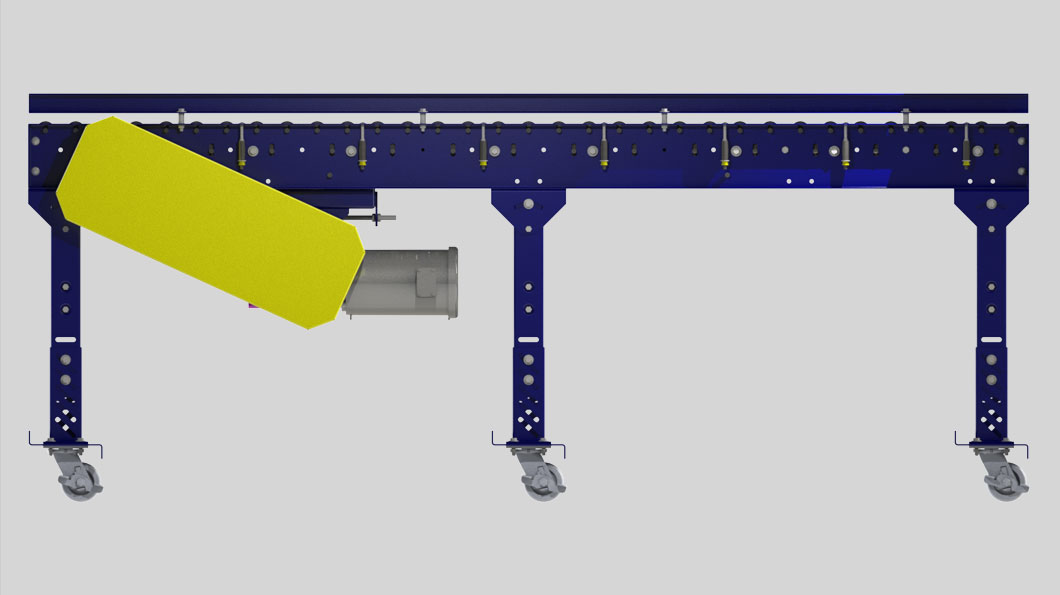

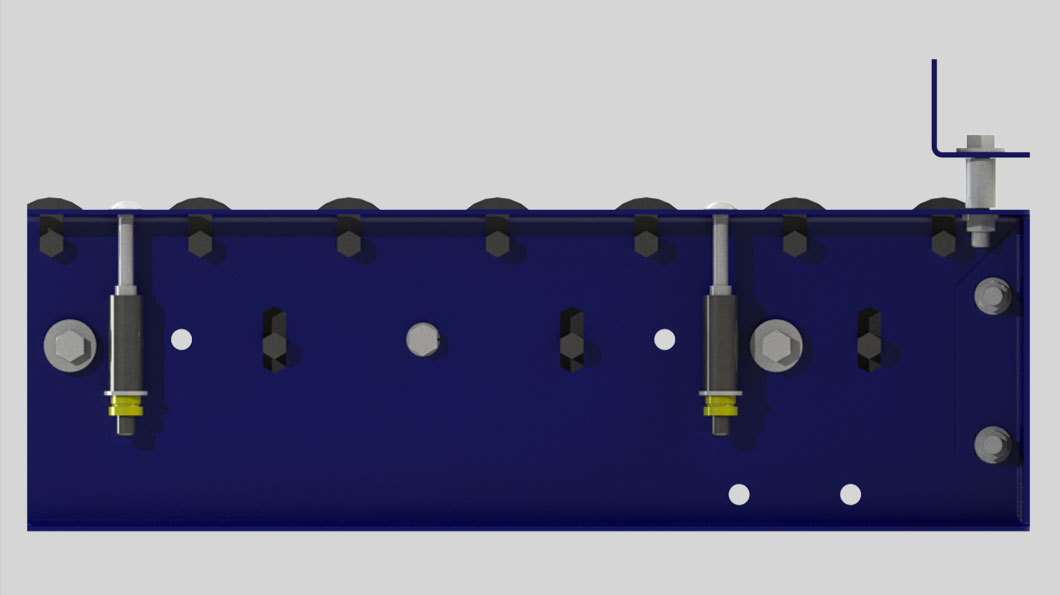

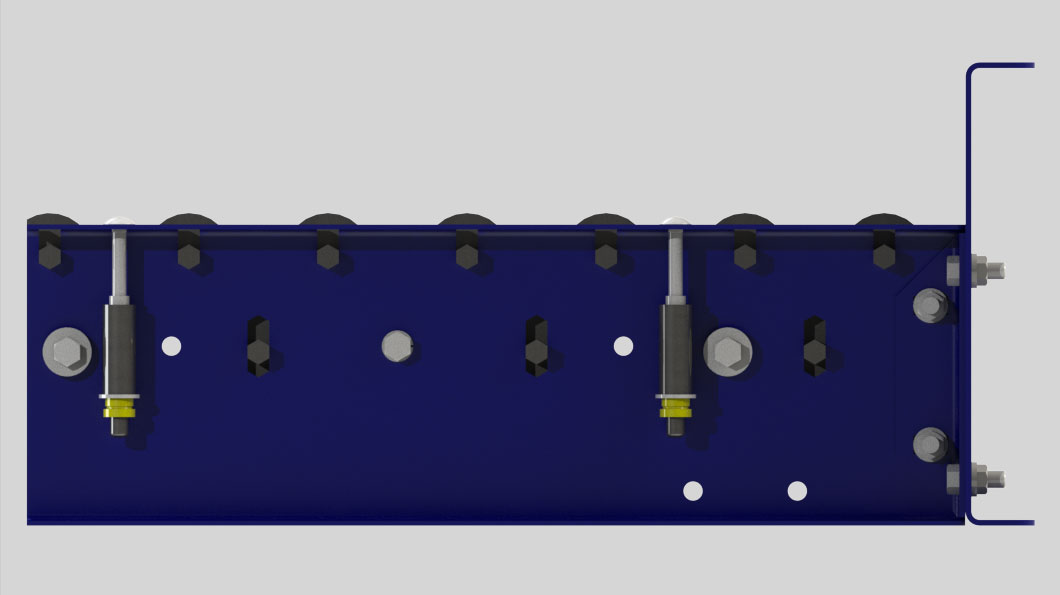

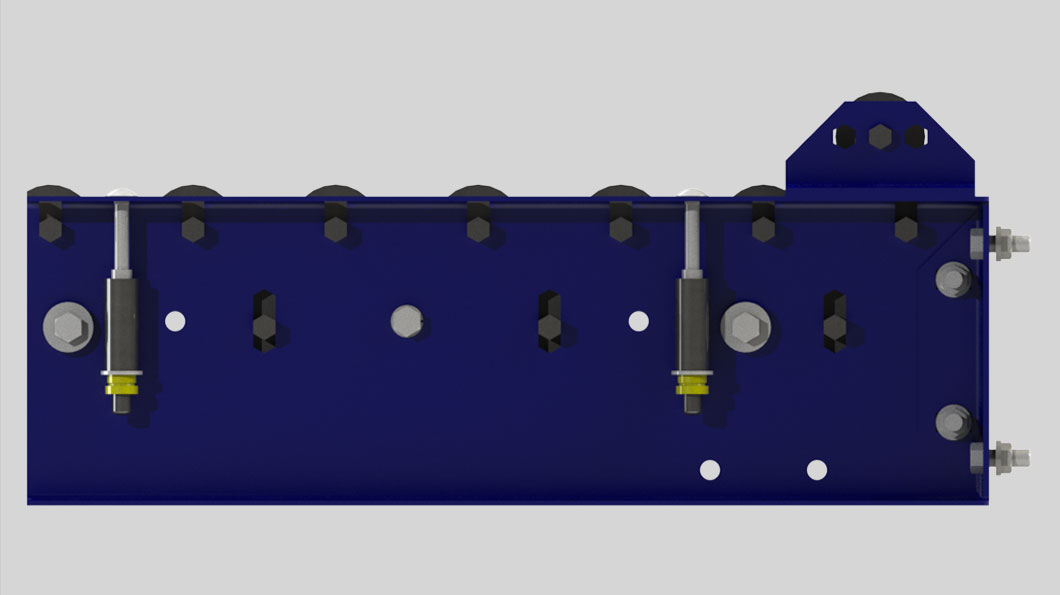

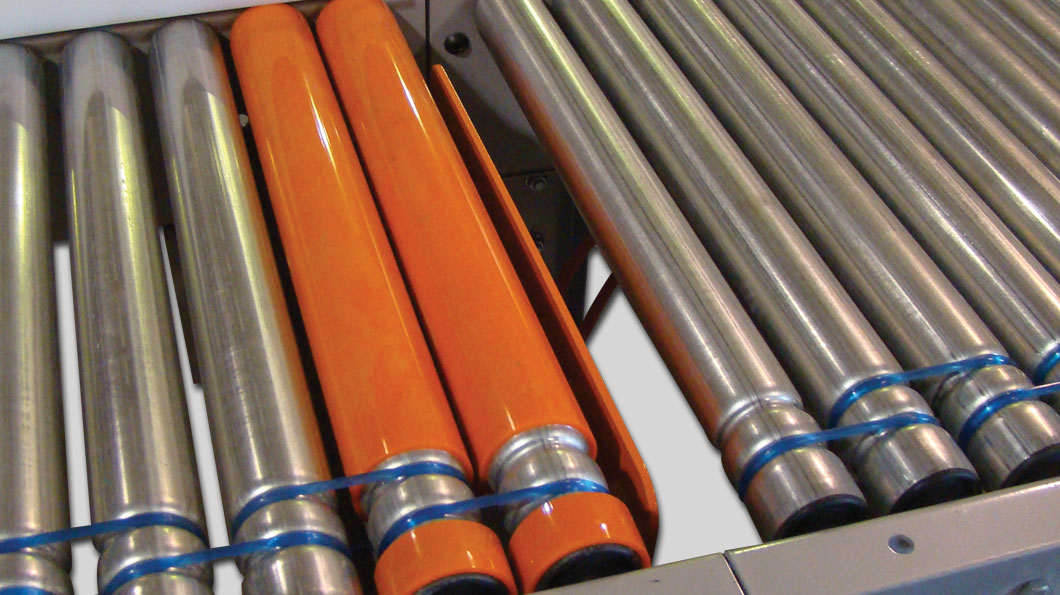

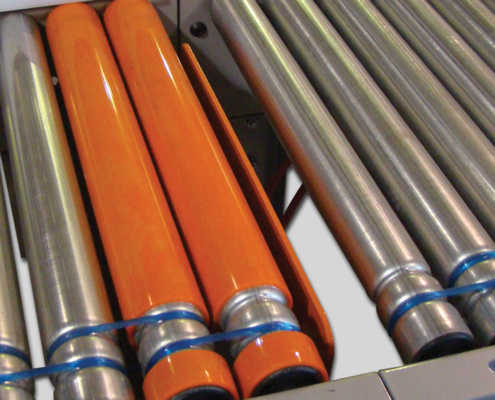

Belt Driven Live Roller

Roller Conveyor with Versatility

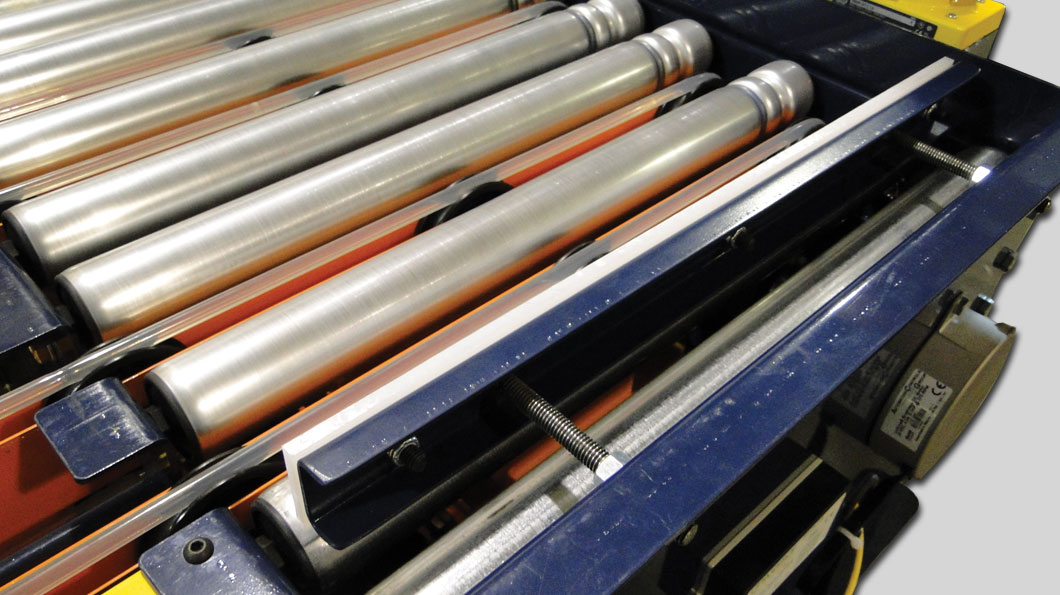

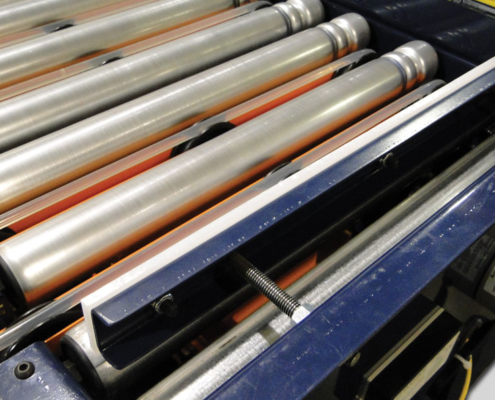

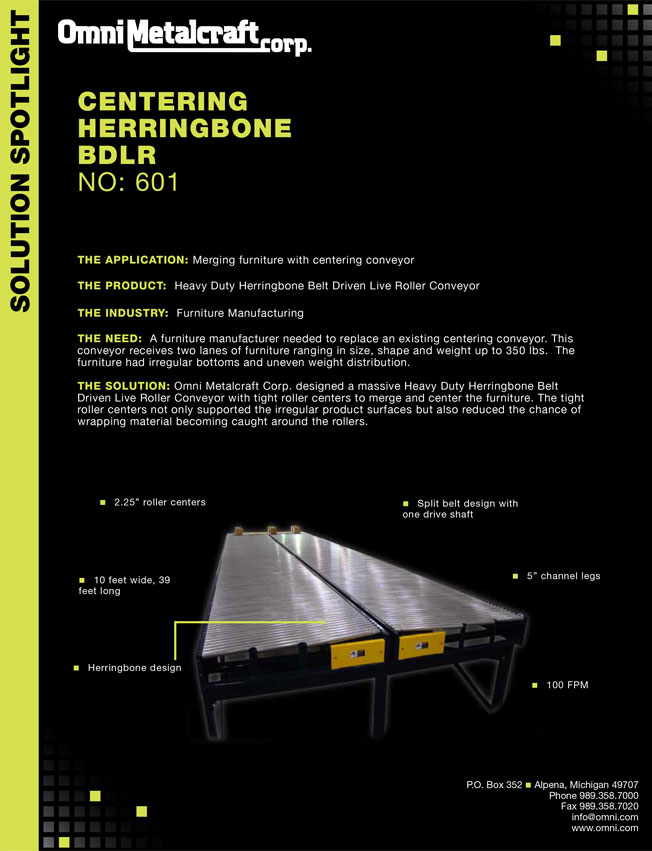

Belt Driven Live Roller (BDLR) Conveyor can handle products of various shapes, sizes and weights. Bolt-together BDLR is ideal for boxes, cases, drums and totes. Welded BDLR is more suitable when conveying heavy loads like appliances and loaded pallets. Accumulating, diverting, merging and transportation are all normal applications for Belt Driven Live Roller Conveyor.

- Versatile means of conveying and accumulation products

- Low maintenance, simple design

- Low back pressure accumulation

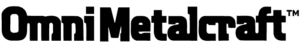

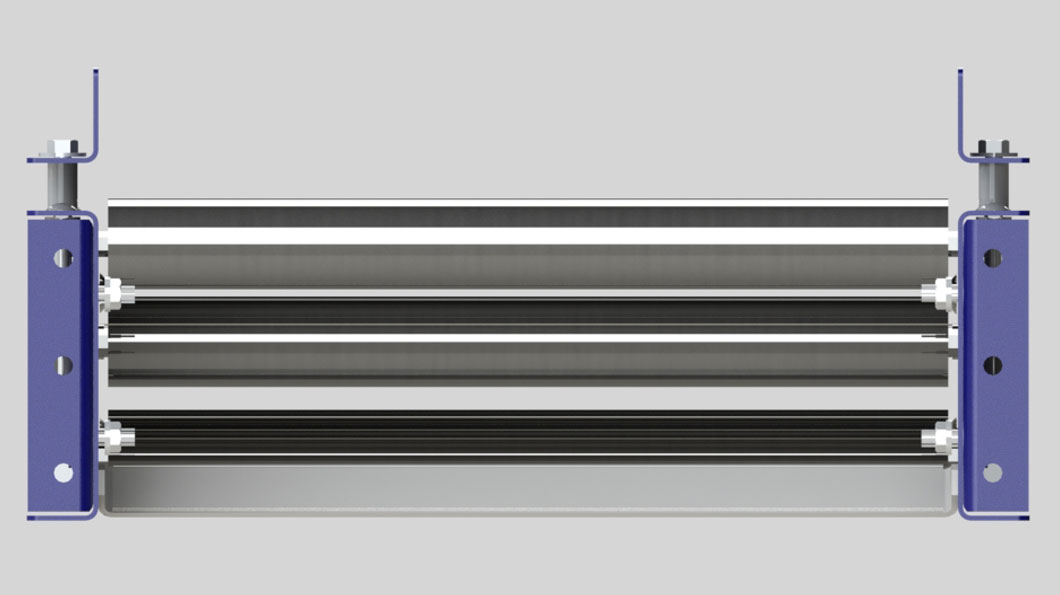

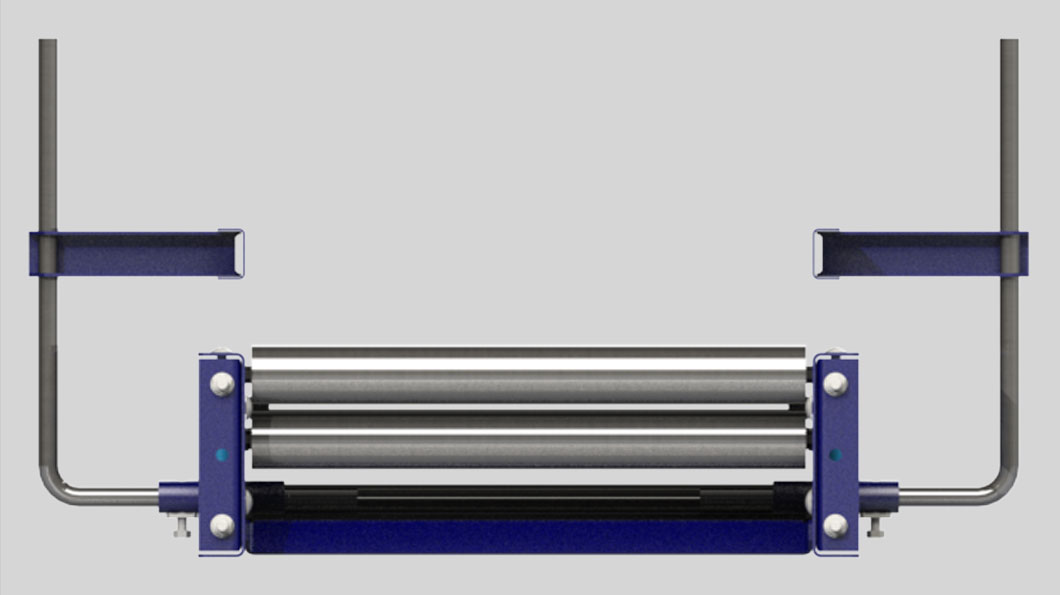

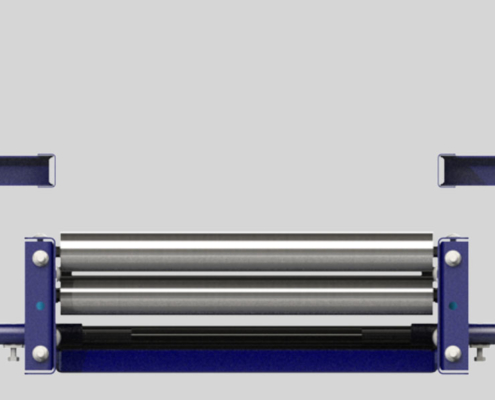

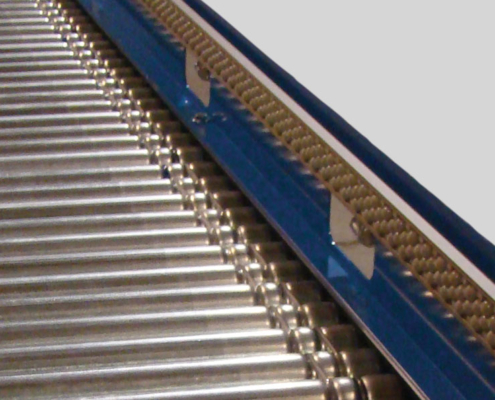

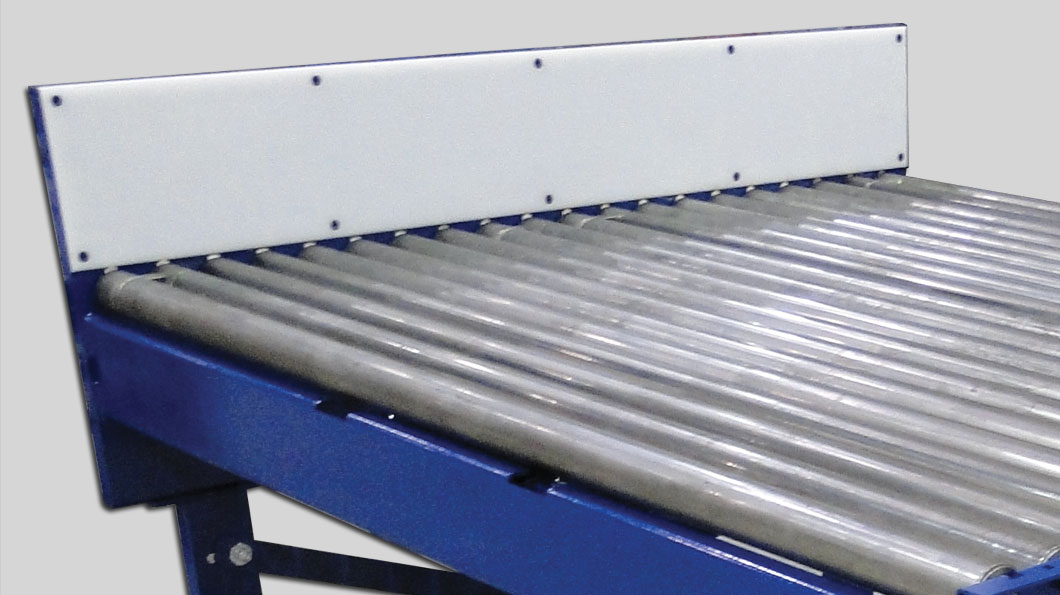

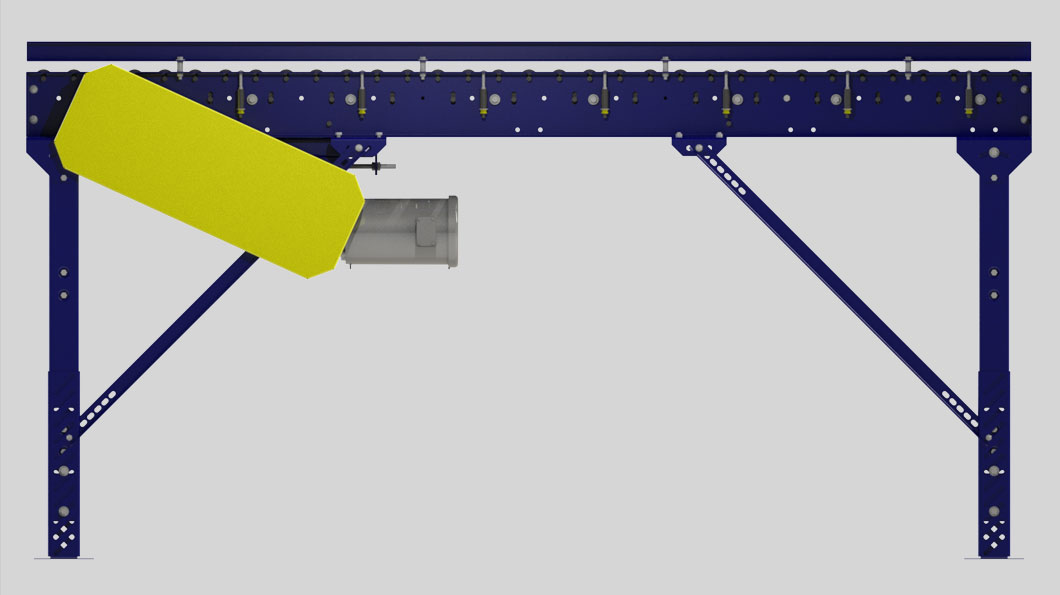

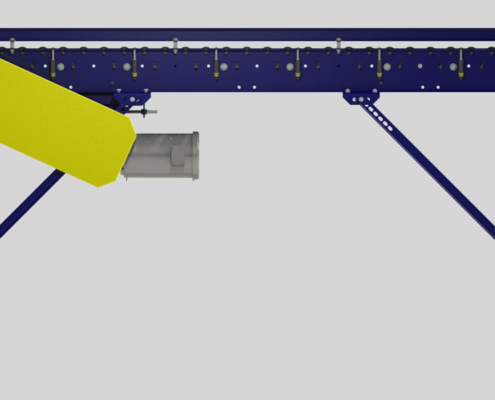

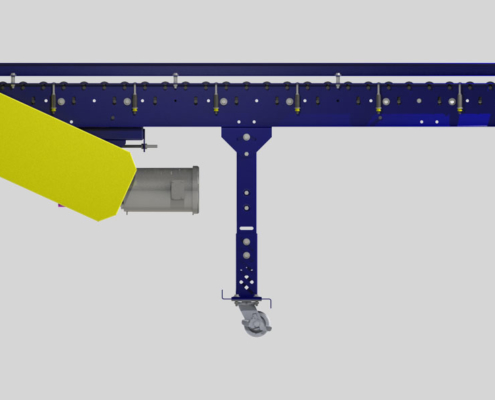

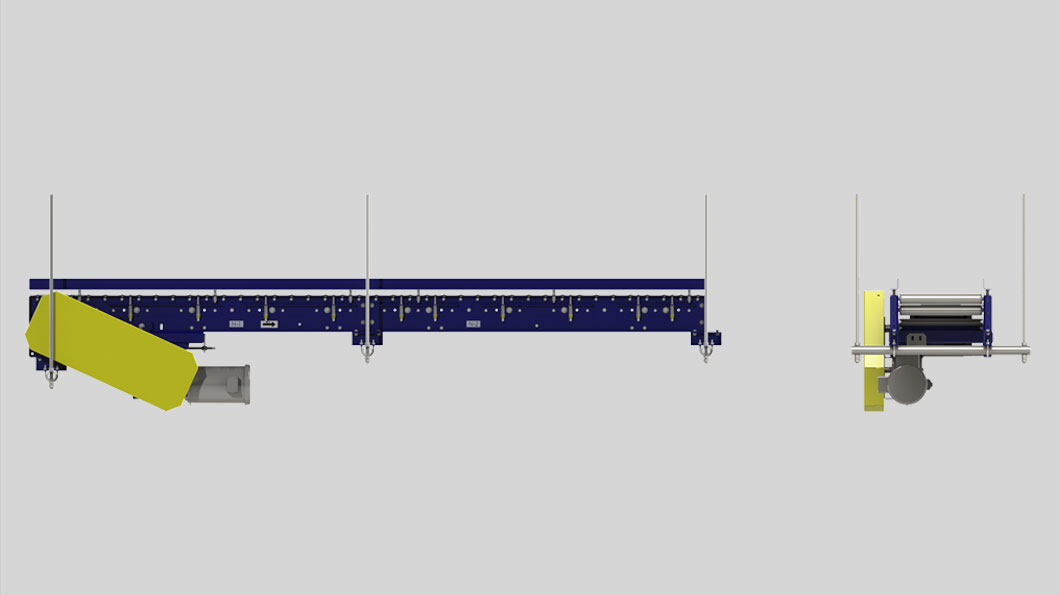

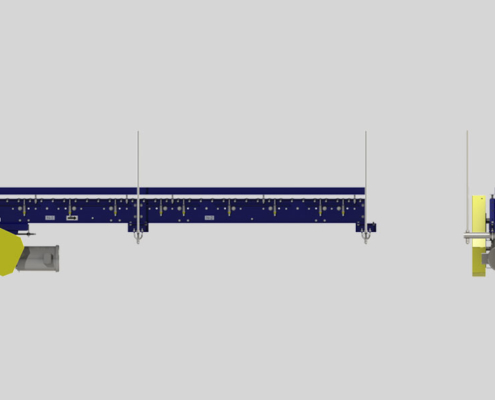

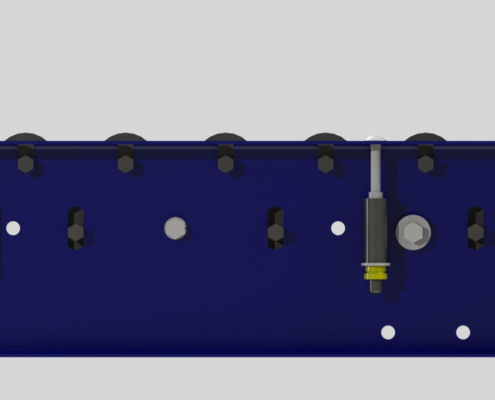

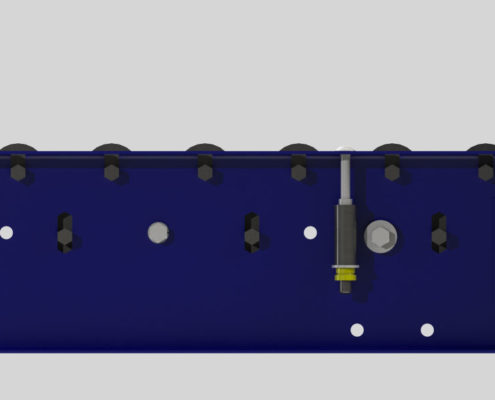

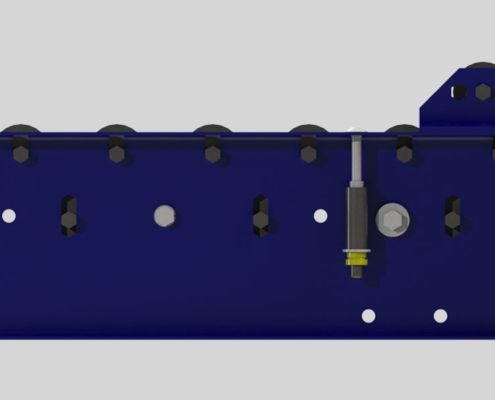

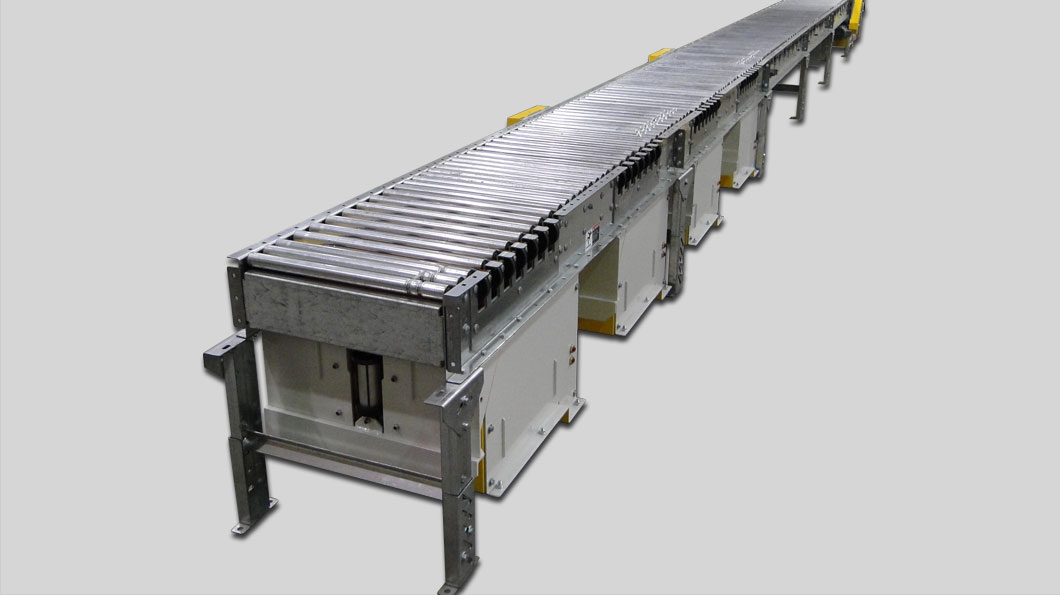

BDLR – Straight

- Light, medium and heavy duty options

- Available in flat belt or V-Belt driven

- Center drives available for reversing applications

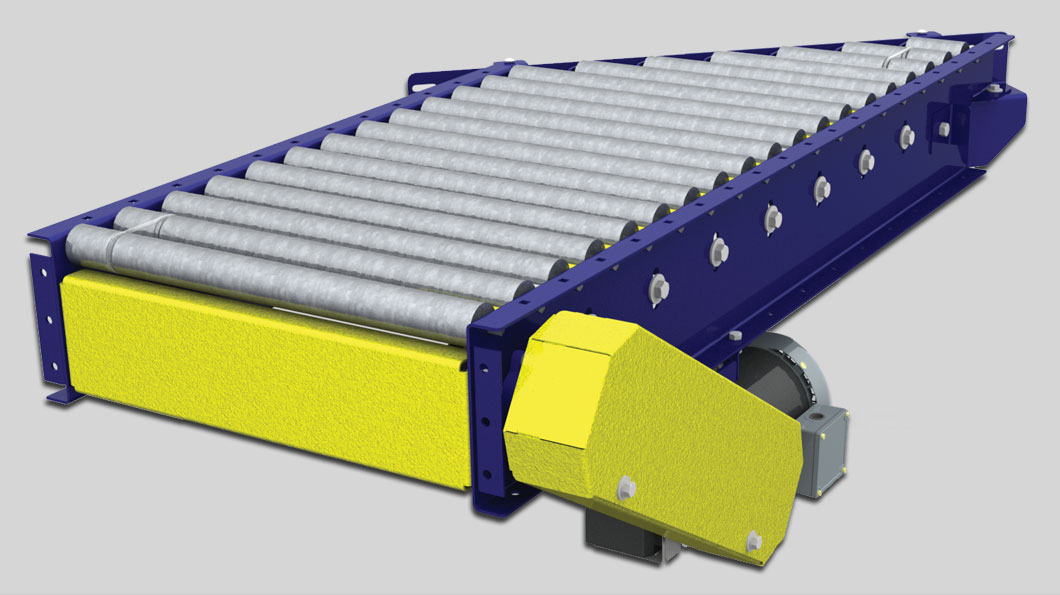

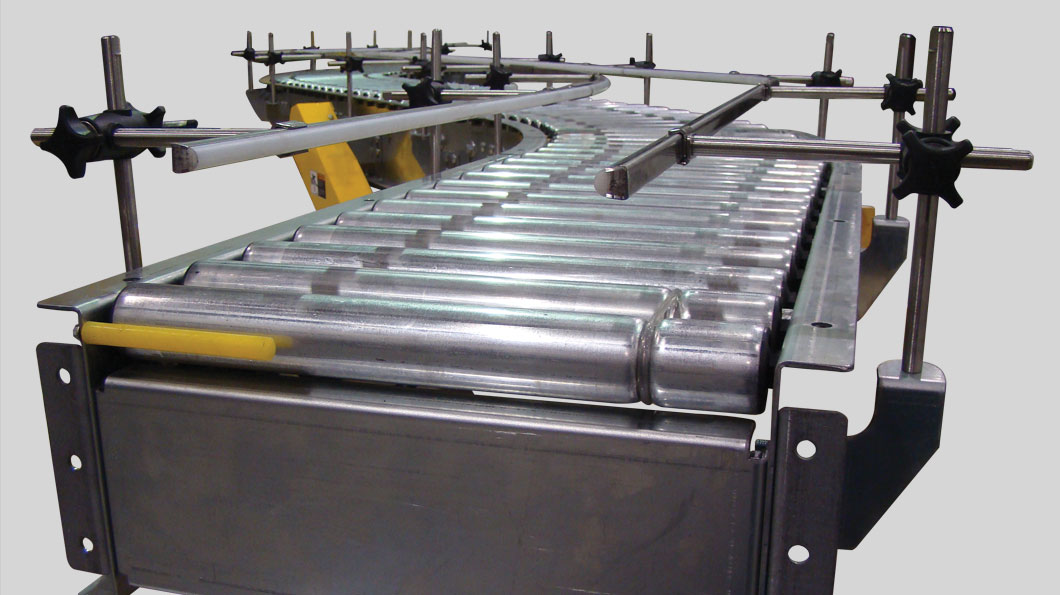

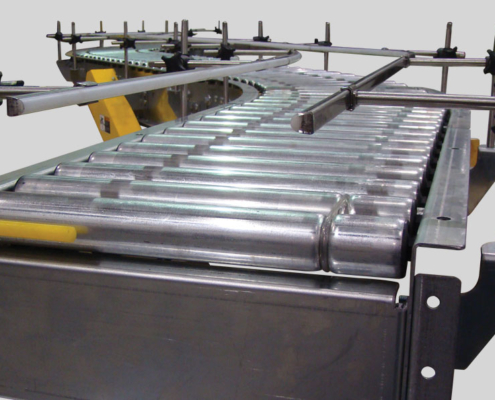

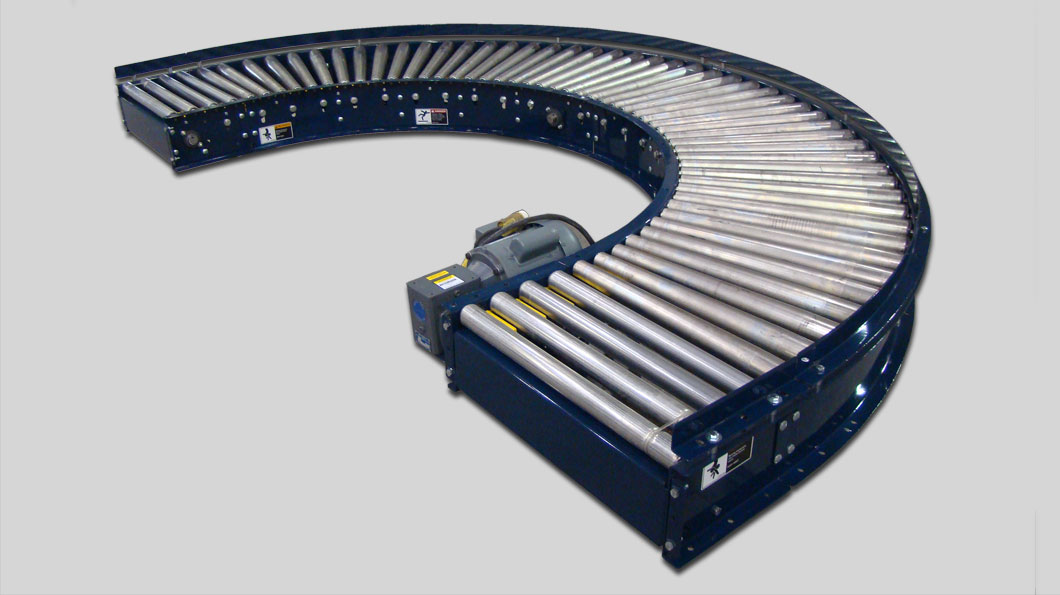

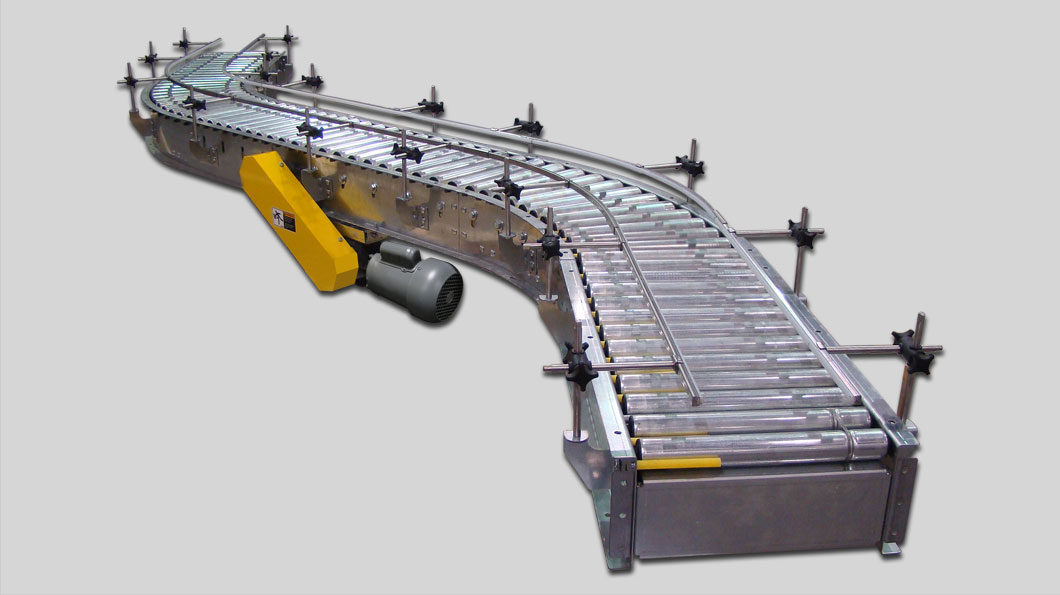

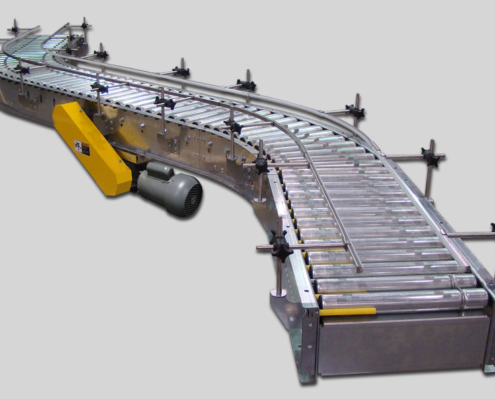

BDLR – Curve

- V-Belt driven

- 30°, 45°, 60° and 90° available

- With drive or slave driven

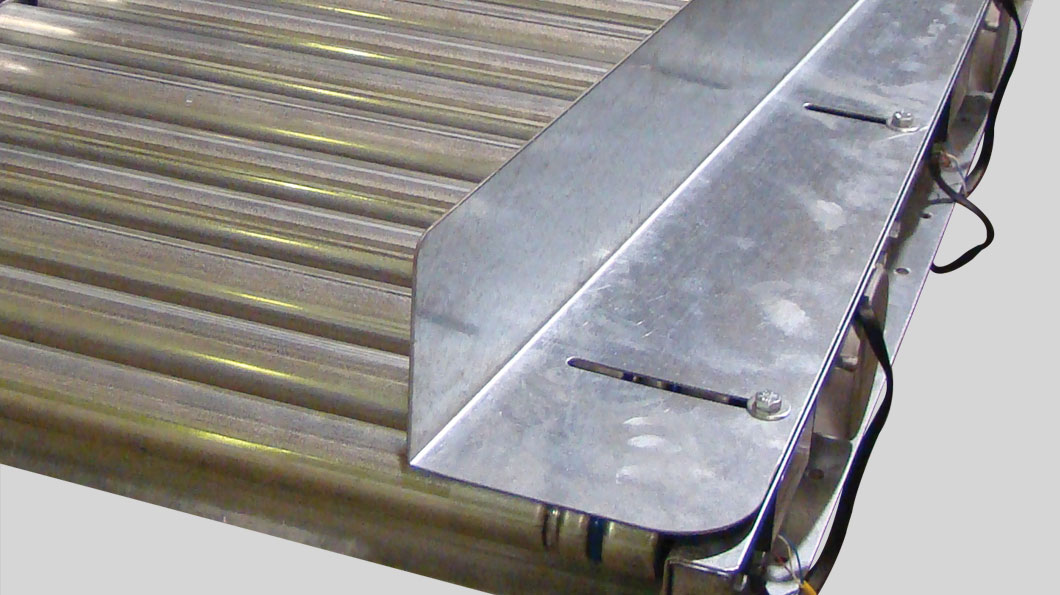

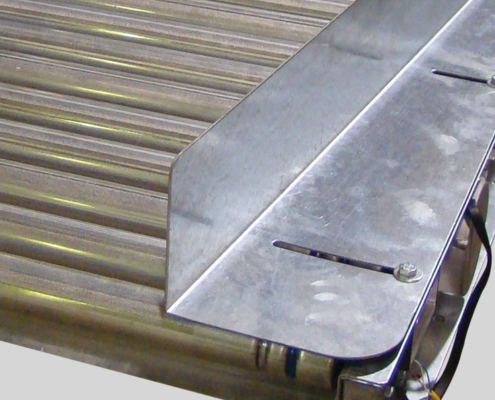

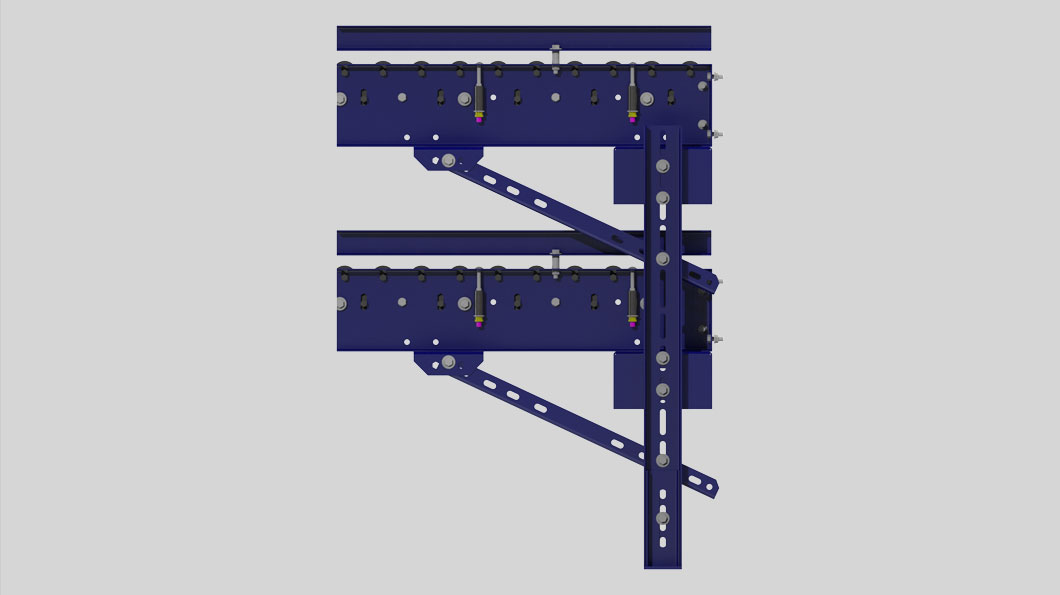

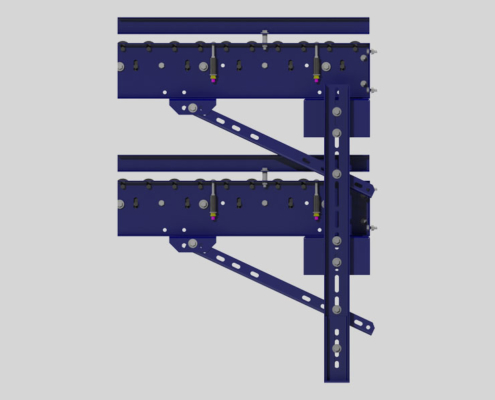

BDLR – Straight Spur

- V-Belt driven

- 30° or 45° available

- With drive or slave driven

- Left or right hand

BDLR – Curve Spur

- V-Belt driven

- 30° or 45° available

- With drive or slave driven

- Left or right hand

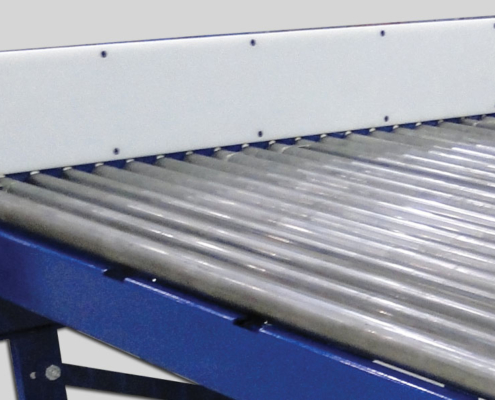

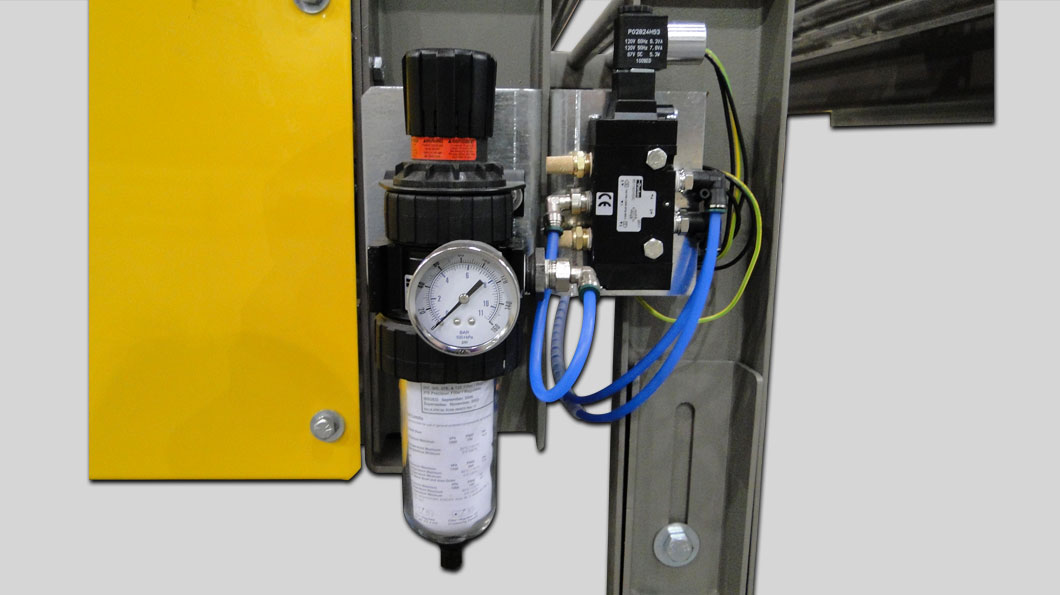

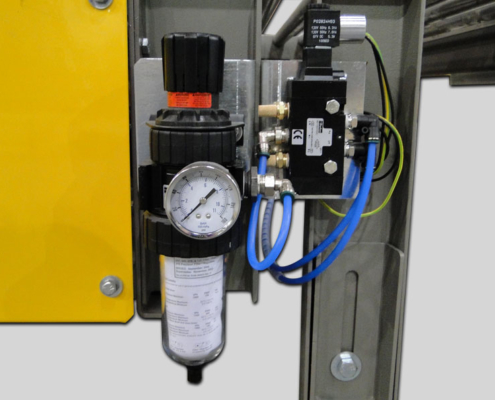

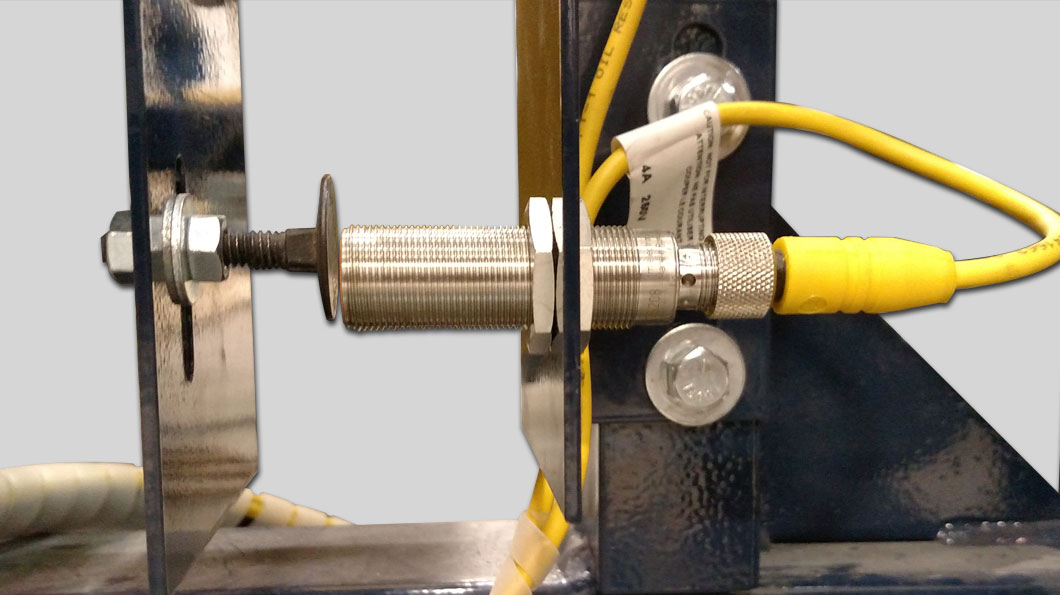

OPTIONAL EQUIPMENT AND DEVICES

▸ Side Guides

▸ Supports

▸ Ceiling Hangers

▸ End Stops

▸ Pin and Blade Stops

▸ Roller Coatings or Sleeves

BDLR CONVEYOR RESOURCES

▸ Photos

▸ Quote Worksheets (PDF)

▸ BDLR Conveyor Literature