Please click on ACCESSORIES or CONTROLS below to see that content

Accessories – Material Handling Products, Service and Solutions

Omni Metalcraft Corp. offers a wide range of accessories to optimize conveyor for your specific application. For your convenience, we also offer replacement parts and components such as bearings and rollers.

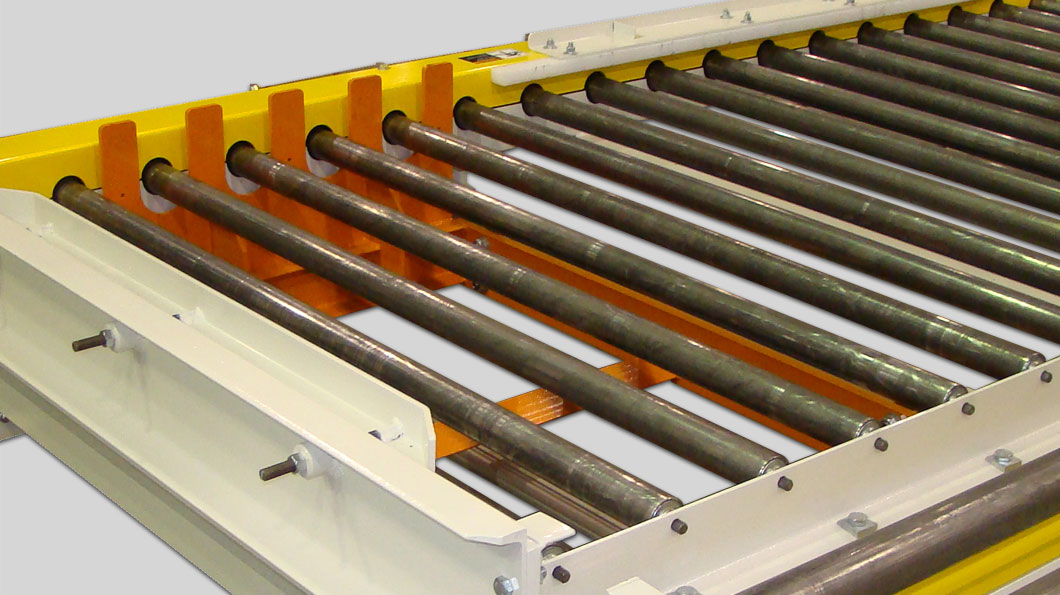

Brake Rollers

Brake rollers are installed below gravity conveyor rollers to provide speed control to the product. Depending on the speed of the product, the brake roller will adjust the amount of braking force to slow the rotation of the contacting rollers. Generally used with gravity conveyor runs, brake rollers will control the flow to prevent damage to product or the material handling equipment. This style of speed control can be used in many environments such as wet, hot and cold conditions.

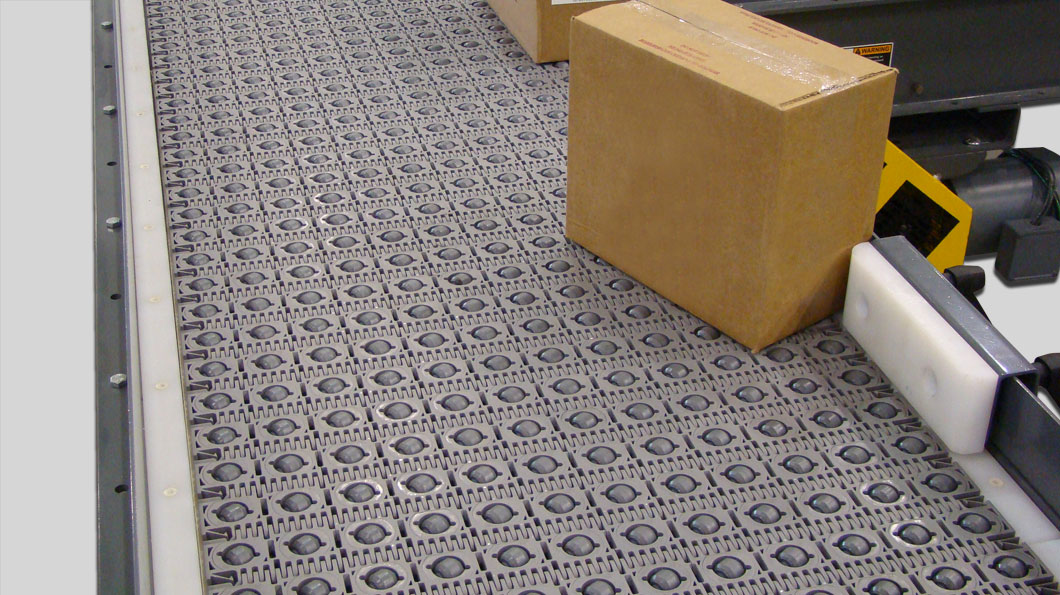

Bump Turn

Case turning is effectively achieved using a bump turn on Intralox’s patented 45° and 30° Activated Roller™ Belt (ARB). The size and style of bump turn will vary with the product. We also provide a retractable bump turn where selective case turning is needed.

Crowder Device

Crowder Devices are normally used to position pallets or racks for utilization by a robot. Crowder Devices are cylinder actuated with custom designed rams to “crowd” or push your product into a consistent and repeatable position on the x and y axis every time. They can be used to hold product in place while being loaded or unloaded.

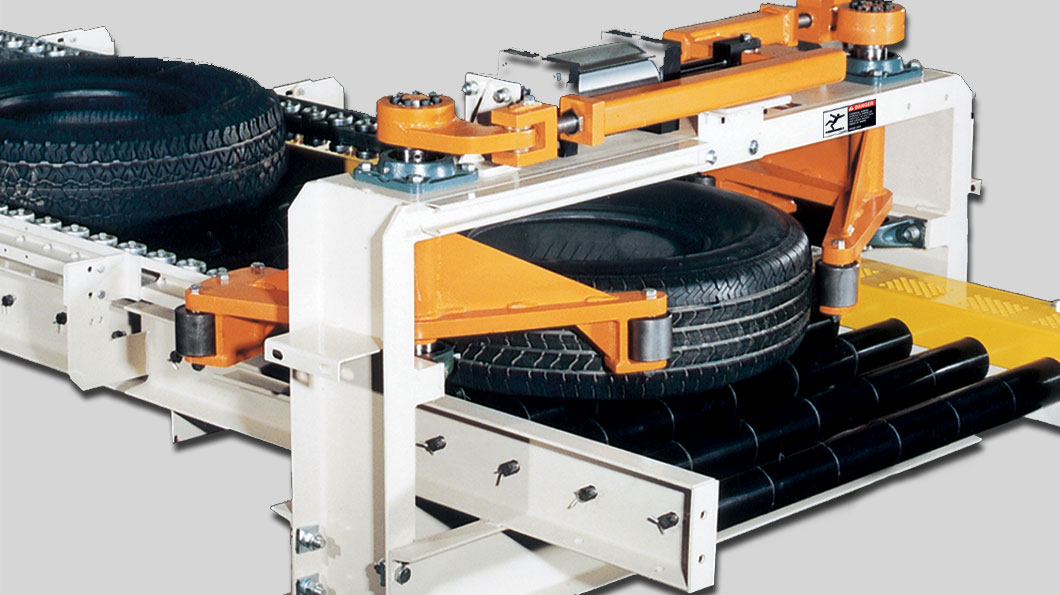

Escapements

Escapements are designed for round products such as barrels, pails, or tires. They control the flow of product by releasing one unit at a time. Escapements are typically mounted to straight CDLR sections and are operated pneumatically. Optional equipment includes limit switches for arm positioning and pneumatic valves.

End Stops

Spring Gates

Spring Gates provide for passage of personnel or equipment through a conveyor line. Gates are spring assist or gas cylinder operated for ease of operation. Gates are available in standard lengths and between frame dimensions, but are also designed for custom applications.

Side Guides

Side guides come in two main styles; adjustable or fixed. There is a variety of additional options available for product guarding. In many instances, products of various shapes and sizes can be simultaneously loaded onto a conveyor in various orientations. A chosen style of “guiding” will allow the product to hold this orientation through the run. Guiding can be achieved via adjustable (width & height) or fixed guides.

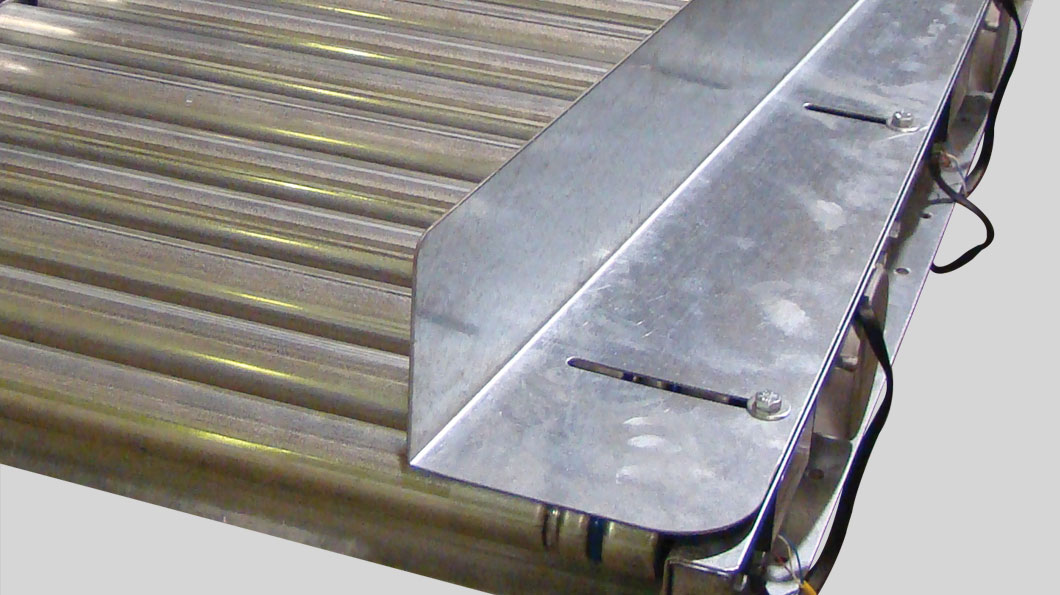

Ceiling Hangers

Ceiling Hangers are used for overhead conveyors. Hanging a conveyor from the ceiling frees up space for other equipment to pass underneath or allows for passageways. Some components equipped for hanging have additional spreaders and reinforcements to maintain structural integrity and rigidity.

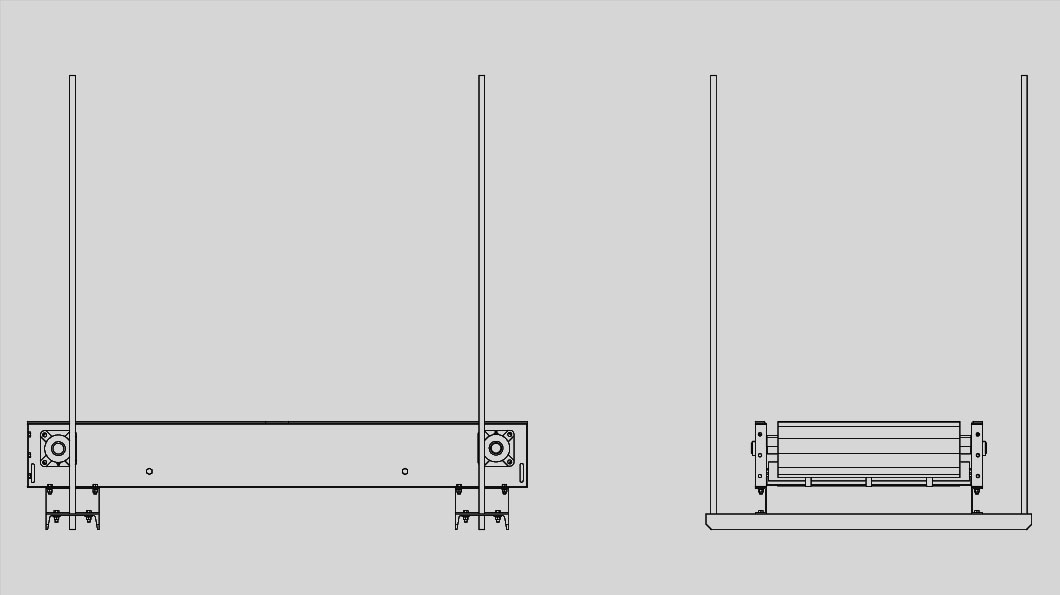

Leg Supports

Temporary and permanent leg supports are available in welded or bolt-together construction. “H” style supports are used in light or heavy duty applications and are adjustable for various top of leg requirements. Tripod style supports are portable and easily adjustable. Supports can be fitted with casters to provide conveyor mobility. We also provide a complete line of multi-tier supports.

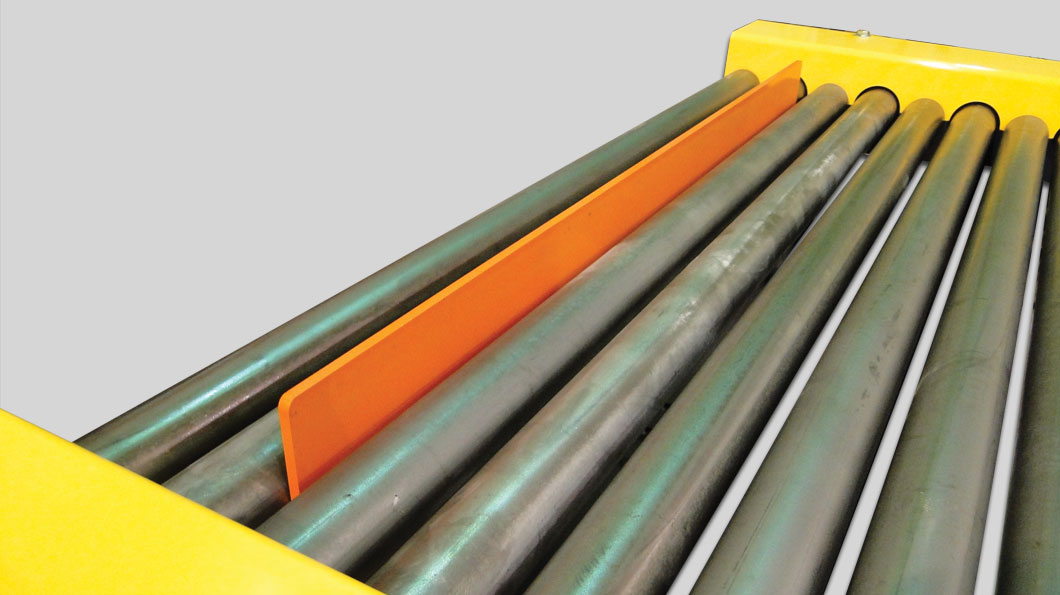

Pop Up Stops

Pop Up Blade Stops and Pin Stops fit between conveyor rollers and extend above the top of roller to stop products. While Blade Stops are used for boxes or pallets, Pin Stops are for round products such as barrels, pails, or tires. Pop Up Stops are typically pneumatic and control product flow by releasing one unit at a time. These stops are mounted within straight conveyor sections. Optional equipment includes limit switches for up/down positioning and pneumatic valves.

Pusher

Omni Metalcraft Corp. builds pneumatic pushers and hydraulic pushers with a full range of capacities, styles and strokes. Pushers can be added to our conveyors for nearly any application.

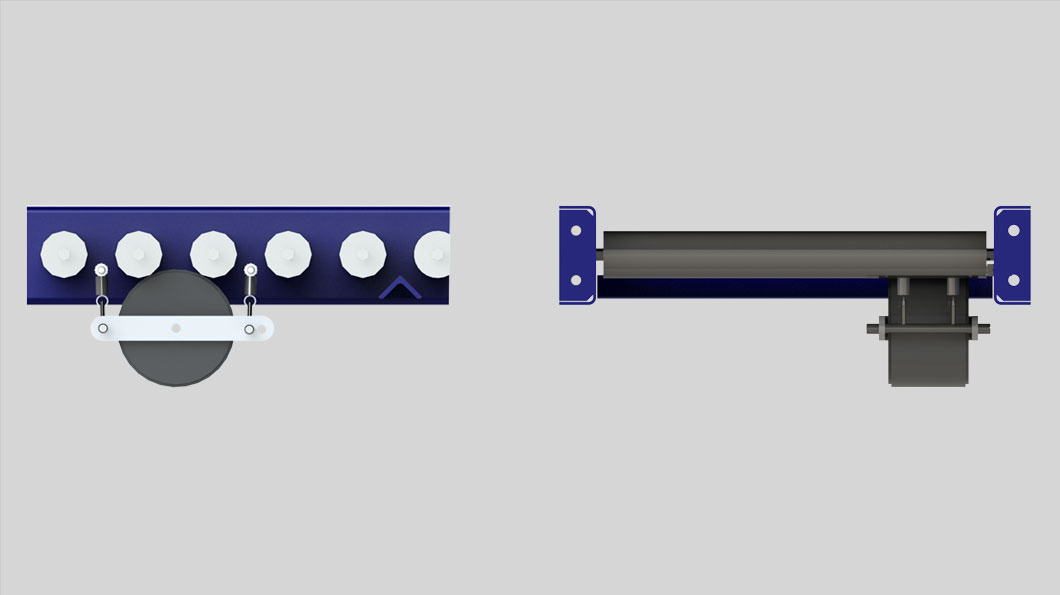

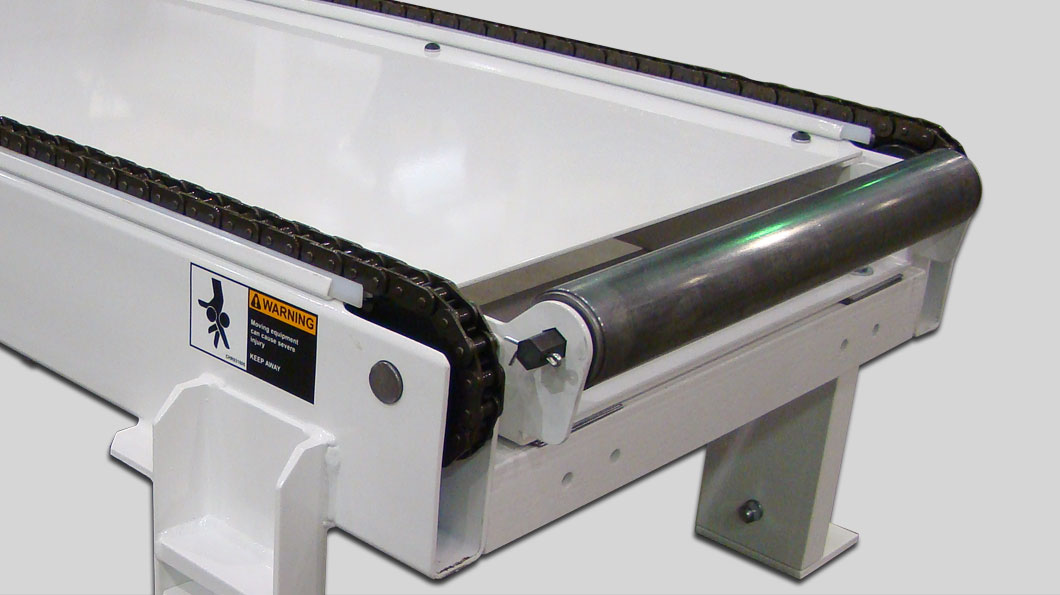

Roller Brake

Roller brakes are used to stop a zoned area of rollers on conveyors like Belt Driven, Lineshaft Driven, Chain Driven Live Roller and Gravity Conveyors. Roller Brakes can be actuated pneumatically, mechanically or manually. Roller brakes are ideal at work stations where the product needs to be stopped momentarily.

Transition Rollers or Plates

Transition Rollers or Plates are used to bridge the gap between conveyors and facilitate product transition. Transition rollers are either slave-driven or non-powered gravity rollers. Transition plates are custom built per application.

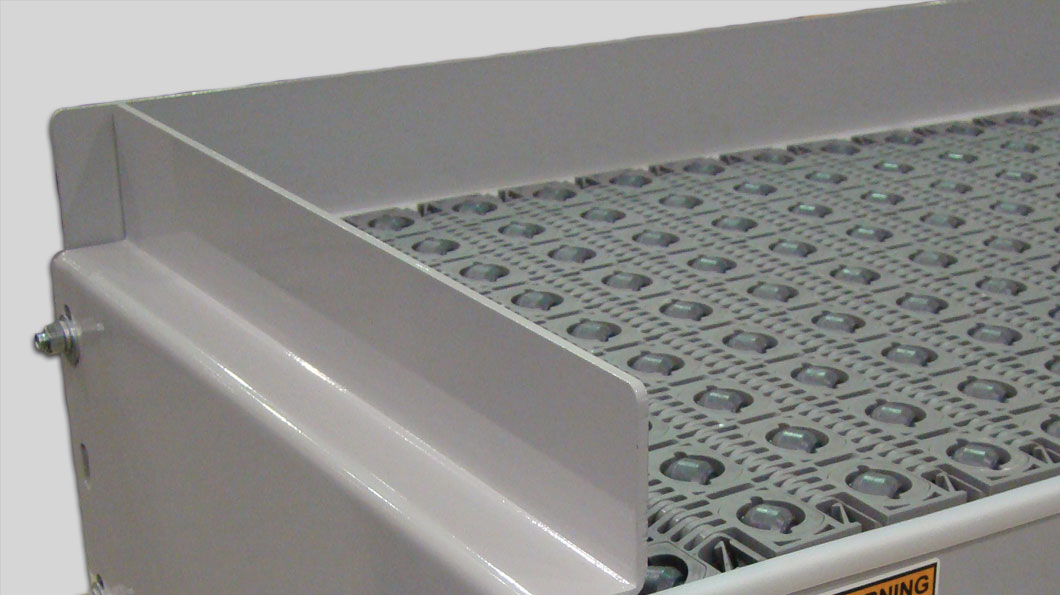

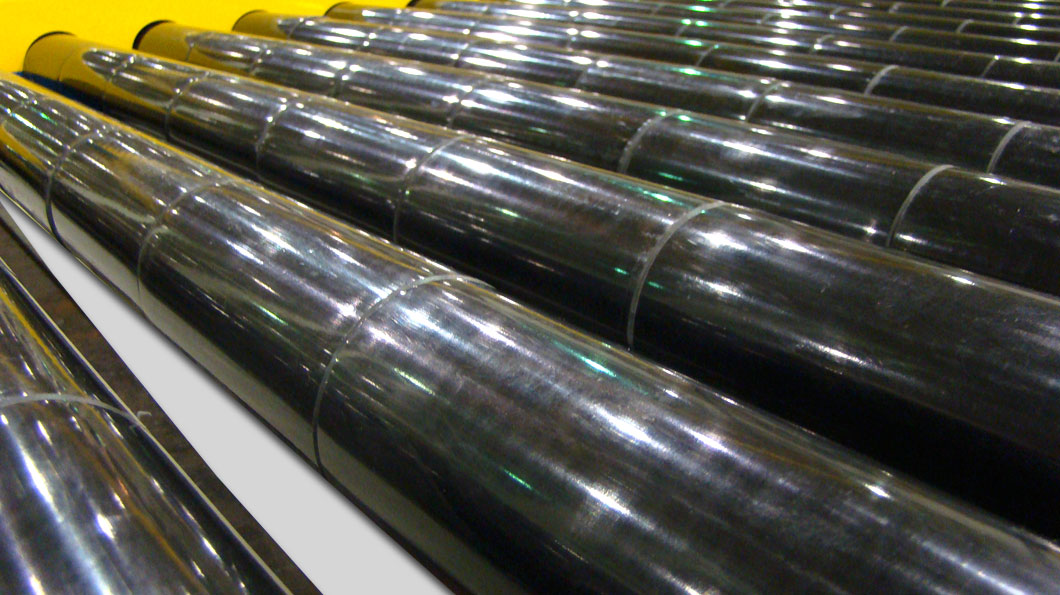

Ultrex® Sleeves

Ultrex® sleeves are high impact plastic sleeves that fit loosely over rollers to enable product accumulation on powered conveyor. The sleeves are not fixed to the rollers, but there is enough friction between rollers and sleeves for products to convey normally. When products are stopped the sleeves stop with the product, preventing product damage, and the rollers continue rotating inside the sleeves. The smooth surface of the Ultrex® slides freely over metal rollers without damaging the sleeve or the roller.

Dents in tubing create stress points that can fatigue the material over time. This makes the tube susceptible to permanent deflection where it can become bowed and out of round. Ultrex® sleeves resist denting much better than metal roller tubes. They also distribute impact loads across the length of the tube preventing further deflection and damage. If Ultrex® sleeves are damaged they are much easier and more cost effective to replace than rollers.

Controls – Options to Customize your Product

Omni Metalcraft Corp. has put together multiple controls packages that help complete the customization of many of our products. From starters to emergency stops and limit switches, we offer the controls to optimize the equipment’s performance.

AC Controller

AC Controllers offer a wide range of options for motor controls such as variable speed, soft start/stop, preset speeds and multi-motor control. The standard controller comes in a Nema 1 enclosure.

AC Variable Speed Drives

- Drives range up to 600VAC and 20 HP

- Standard drive is capable of a 10:1 speed ratio up to 5 HP

- Available in single or three phase; non-reversing or reversing

- Standard enclosure is rated Nema 1. Can be upgraded to Nema 4X/12

- Can be combined with a remote mounted push button station, foot pedal or hand pendant

- A photo eye can be wired to the starter and used for stopping the conveyor as well as an auto-stop/restart function

- Can be shipped loose, mounted only or mounted to the conveyor and wired to motor

- Power cord and plug available for 115v- 1ph- 60 HZ up to 3/4 HP, power cord less plug only for other voltages

- Other control options and VFDs are available

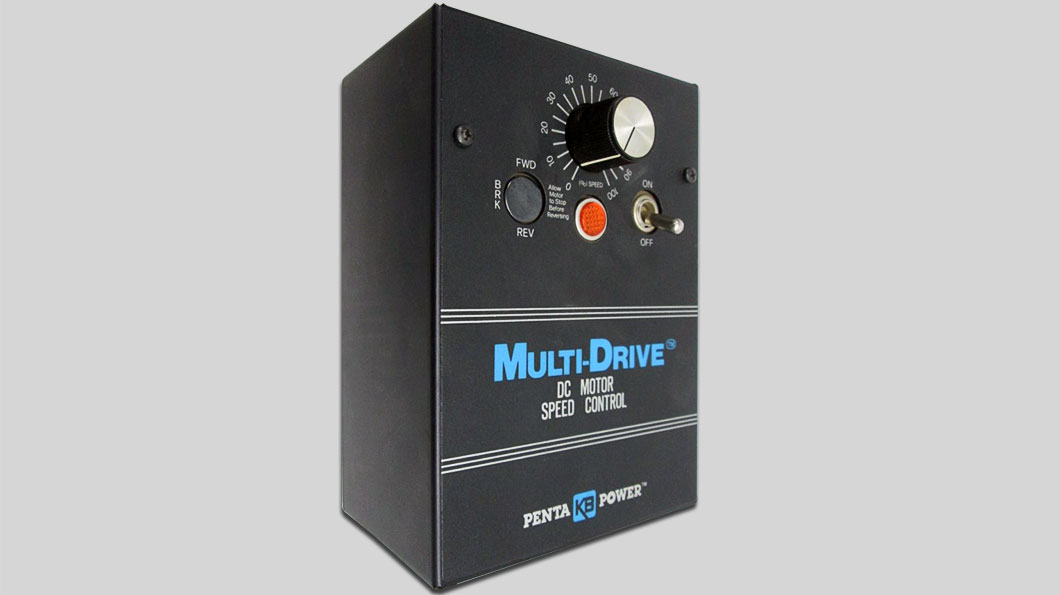

DC Variable Speed Drives

A DC controller offers a cost effective solution to variable speed motor control. Standard drive includes armature and line fusing, overload protection, power on indicator, speed pot and an on/off switch. It also contains internal adjustments for soft start/stop and maximum/minimum speeds. Enclosure is a Nema 1.

DC Variable Speed Drives

- Controller has selectable input line voltage of 115 or 230V AC single phase. The output voltage will be 90 or 180V DC depending on input voltage

- Standard drive is capable of a 10:1 speed ratio up to 2 HP

- A Forward/Brake/Reverse toggle switch can be installed in the standard drive for reversing applications

- Standard enclosure is rated Nema 1. Can be upgraded to Nema 4X/12

- Optional drive can be combined with a remote mounted push button station, foot pedal or hand pendant

- A photo eye can be wired to an optional drive for stopping the conveyor as well as an auto-stop/restart function

- Can be shipped loose, mounted only, or mounted to the conveyor and wired to the motor

- Power cord and plug available for 115V-1ph-60hz up to 3/4 HP, power cord less plug only for other voltages

- Standard DC controllers is not to be used with any other control devices

Disconnect Switches

Our standard disconnect switch is an IEC style, fully enclosed Nema 4x, non fused, 3-pole, 600VAC, 30 amp with auxillary contact.

Disconnect Switches

- Can be shipped loose or mounted and wired

- Can be shipped loose with cables for customer installation in the field

- Available in Nema style fused, Nema 1 or 12 for short circuit protection applications

Emergency Stops

A cable pull emergency stop can be mounted to the conveyor and provide the operator with a more convenient and safer control location. Up to 240 ft. of cable can be used per switch. A mushroom head pushbutton operator station can be remote located on conveyor.

Emergency Stops

- Enclosure is rated Nema 4

- Other safety device options are available

- Pushbutton station or cable pull emergency stop switch and cable kit can be shipped loose, mounted only or mounted to conveyor and wired to a junction box or motor controller

IEC Motor Starter Packages

IEC style magnetic motor starter with overload protection, mounted in a Nema 4x polycarbonate enclosure. Up to 600VAC.

IEC Motor Starter Packages

- Offers significant cost savings over Nema style starters

- Available in single or three phase; non-reversing or reversing

- Enclosure can be upgraded to:

- Nema 4/4x (stainless steel washdown, corrosion resistant)

- Nema 7/9 (explosion proof)

- Can be shipped loose or mounted to conveyor and wired to motor

- Can be combined with a remote mounted push button station, foot pedal or hand pendant

- A photo eye can be wired to the starter and used for stopping the conveyor as well as an auto-restart function

Non-Reversing Manual Starter

A non-reversing, Nema type manual starter in a Nema 1 enclosure. Functions as a simple on/off switch for motor control.

Non-Reversing Manual Starter

- Up to 2 HP at 115/230VAC, single phase

- Up to 2 HP at 230VAC, three phase

- Up to 2 HP at 460VAC, three phase

- Can be shipped loose, mounted only or mounted to conveyor and wired to motor

- Power cord and plug available for 115V-1ph-60hz up to 3/4 HP, power cord less plug only for other voltages

Please note, this device has no overload or short circuit protection. The manual starter is not to be used with any other control devices.

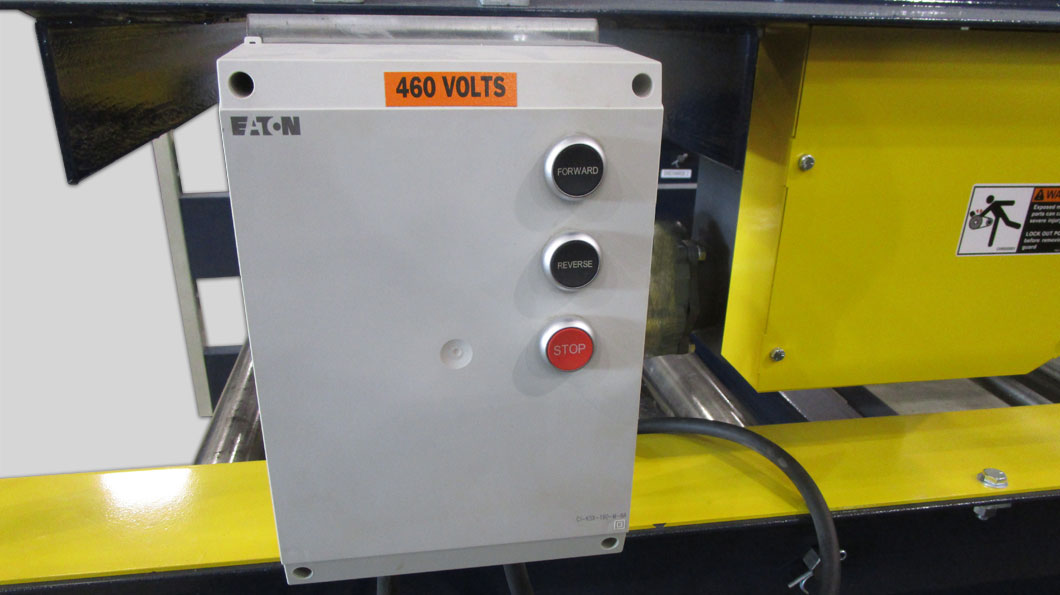

Push Button Stations

A push button station, hand pendant or emergency stop can be remote mounted to provide the operator with a more convenient control location.

Push Button Stations

- Standard enclosure is Nema 4 (polycarbonate)

- Enclosure can be upgraded to Nema 4/4X (washdown, stainless steel, corrosion resistant) or Nema 7/9 (explosion proof)

- Can be shipped loose, mounted only or mounted to conveyor and wired to motor controller or junction box

- Pedestal mount is available

- Standard configurations for start/stop, forward/stop/reverse, emergency stop and up/down

- Custom configured operator stations are also available

- Custom hand pendant configurations are availible

Foot Pedal Controller

The foot pedal controller is a standard option for operation of equipment when the hand pendant is not desired.

Foot Pedal Controller

- Available in a single, double or triple switch configuration (guard included) for up/down or start/stop applications

- Pneumatic foot pedal available for direct actuated applications

- Enclosure can be upgraded to Nema 4/4X (washdown, corrosion resistant) or Nema 7/9 (explosion proof)

- Can be shipped loose, wired to motor controller or junction box

The Nema rated industry foot pedal with guard can be remote located to provide the operator with hands-free control.

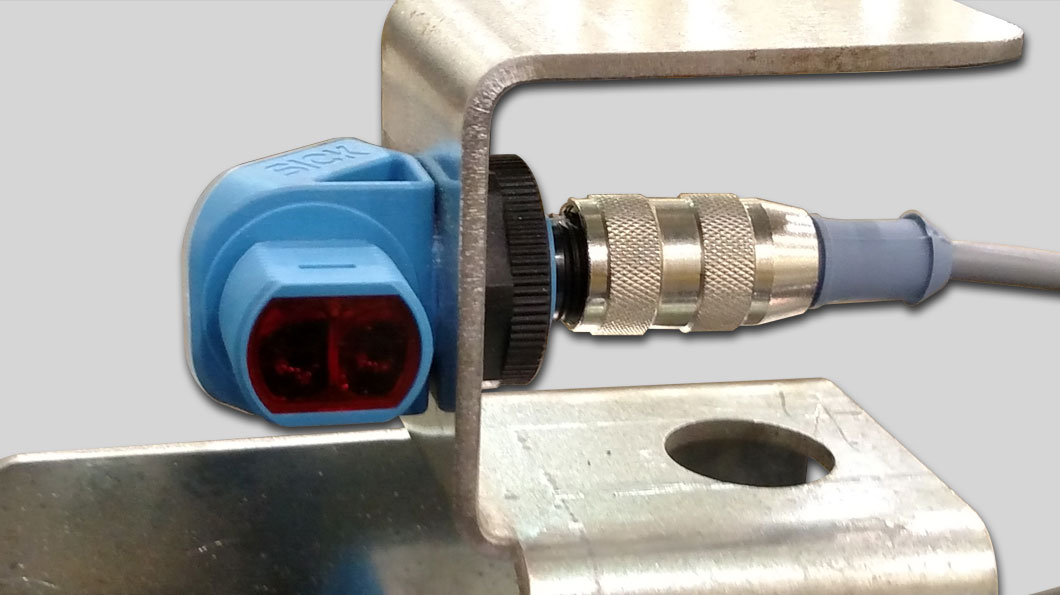

Photo Electric Sensors

Used for “Non-Contact” product detection. The retro-reflective photo-eye with a 3″ reflector has a 30 ft. sensing distance. It has dry contact outputs, or solid state output depending on applications. It is rated from 70-264V AC or DC. Standard connection is a 5-pin mini style quick connector.

Photo Electric Sensors

- Can be shipped loose, mounted only or mounted to conveyor and wired to motor controller or junction box

- Enclosure is rated Nema 3, 4X, 6P, 12, 13 and IP67

- “DeviceNet” and other photoelectric sensors are available for your customized application

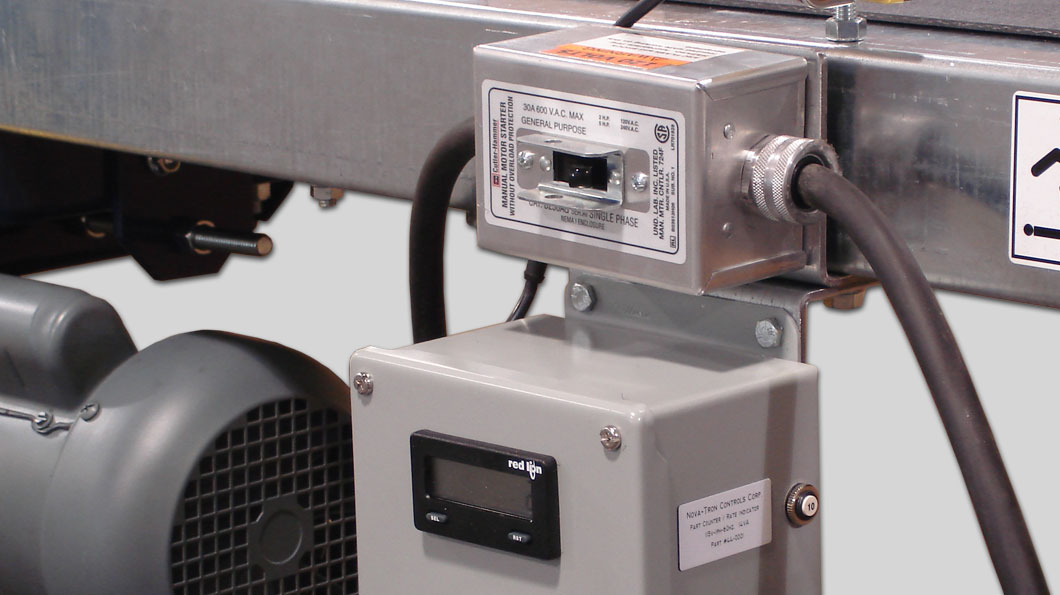

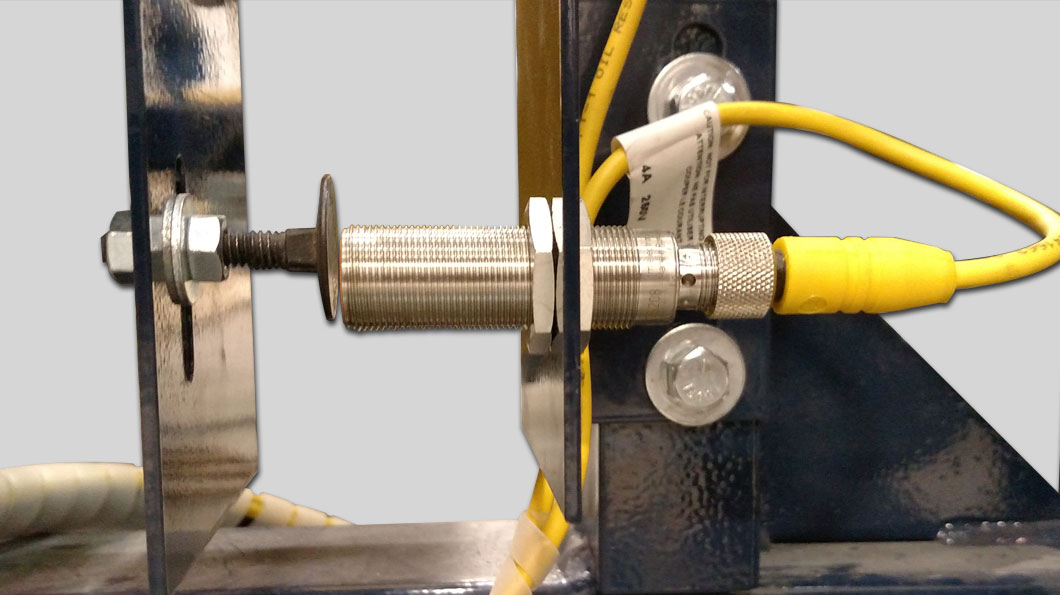

Proximity Sensor

Used for “Non-Contact” machine motion sensing. The standard 18 mm proximity switch has a 10 mm sensing distance. It has one normally open solid state output rated from 20-250V AC, 400 mA. Standard connection is a 6.5 ft (2M) Cable.

Proximity Sensors

- Can be shipped loose, mounted only or mounted to conveyor and wired to motor controller or junction box

- Enclosure is rated Nema 3, 4, 12, 13 and IP67

- “DeviceNet” and other proximity sensors are available for your customized applications

Zero Pressure Accumulation Sensors

Non contacting products move down a conveyor in singulation mode or can be slug released for mass product movement. Complete control packages are available for the accumulating conveyor, either with the use of a standard sensor and PLC system or an optional style sensor that has zero pressure logic self contained in each sensor.

Zero Pressure Accumulation Sensors

- The standard photo-eye and solenoid valve can be placed in each zone for customer controlled zero pressure logic. Components can be wired to a junction box as an option. (See photo electric sensors for complete description of standard photo-eye)

- The optional style sensor and solenoid valve with built in zero pressure accumulation logic can be pre-assembled on the conveyor for easy reconnection at installation, with a considerable cost savings over the standard photo-eye PLC logic.

- Sensors with built-in logic operate at 24VDC. A 24VDC power supply is provided with each system and requires a 115 or 230VAC short circuit protected supply voltage.

- Motor controls can be added to either package for a stand alone system

- Sensors can be shipped loose, mounted only or mounted to conveyor and wired to a junction box. Complete zero pressure control logic systems are also available.

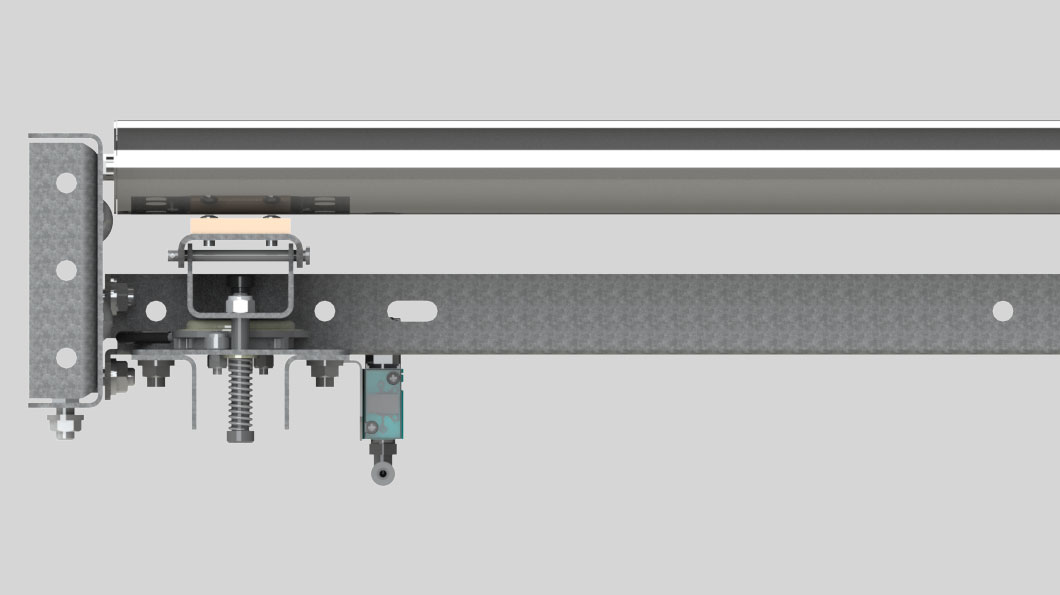

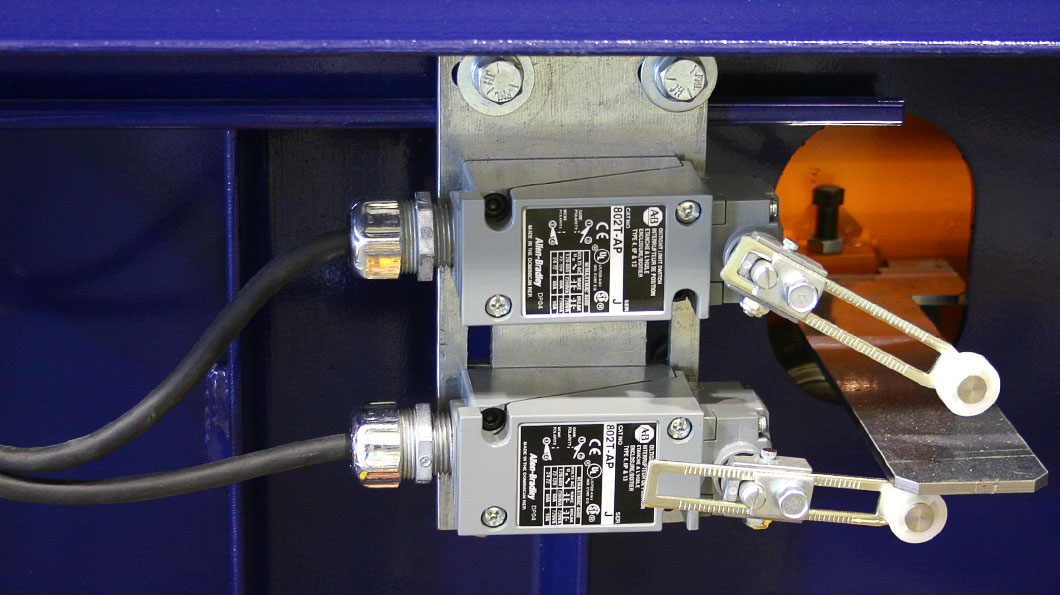

Limit Switch

Used to detect machine motion. The standard limit switch is industrial rated to Nema 4.

Limit Switches

- Enclosure is plug-in style, rated Nema 4, 13 and IP65

- 115 VAC control is standard, 24 VDC is optional

- Can be shipped loose, mounted only or mounted to conveyor and wired to a junction box or motor controller

- Arms for limit switches are also available in a variety of different styles

- Limit switches are available with quick disconnect styles connectors

- “Device Net” and other optional limit switches are available

Reversing Drum Switch

A reversing, manual starter in a Nema 1 enclosure. Use a drum style switch for forward/off/reverse motor control.

Reversing Drum Switch

- Up to 1-1/2 HP at 115VAC, single phase

- Up to 2 HP at 230VAC, single phase

- Up to 2 HP at 460VAC, three phase

- Can be shipped loose, mounted only or mounted to conveyor and wired to motor

- Power cord and plug available for 115v-1ph-60hz up to 3/4 HP, power cord less plug only for other voltage

Please note, this device has no overload or short circuit protection. The manual starter is not to be used with any other control devices.

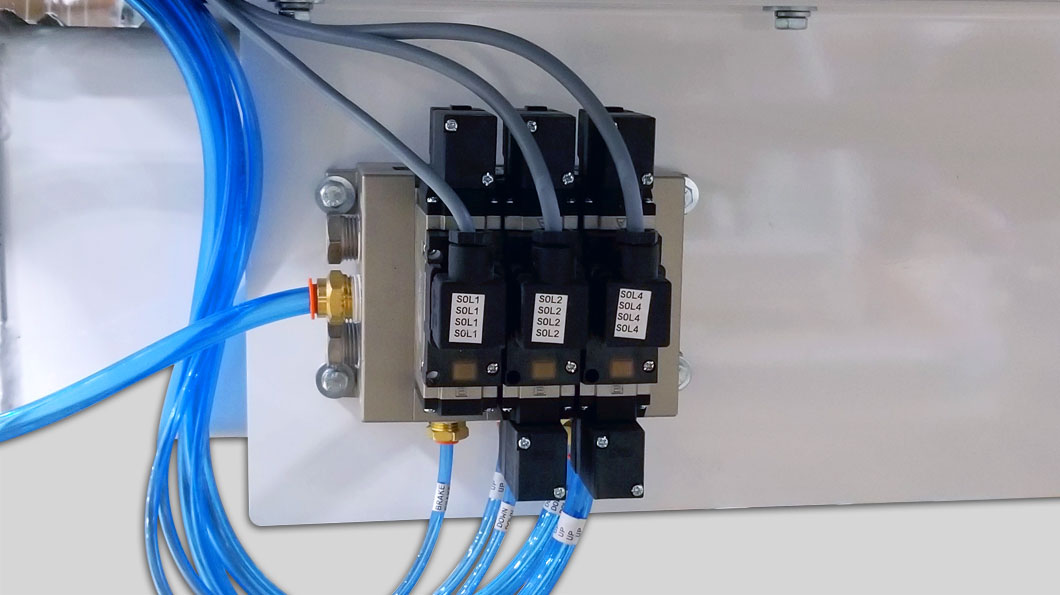

Valve and Valve Boards

For those applications requiring air, we can mount and plumb individual valves or valve boards to control the cylinders and air bags. In larger applications, valve boards can save space and time by mounting valves at one location, and have the ability to lockout these valves during maintenance or troubleshooting. Valves and valve boards can be customized to meet customer specifications and brand names.

Valve and Valve Boards

- Port sizes range from 1/4″ – 1″ NPT

- Standard configurations include: lockout valve, filter/regulator, directional valves, fittings, plugs and mufflers that are needed for the valve board assembly. Lubricators can be added as required.

- Valve and valve boards can be shipped loose, mounted only or mounted and plumbed to the conveyor

- Solenoids can be wired to a junction box. Available in 120VAC or 24VDC coil voltages

- Custom configurations are available to meet customer specifications